How to maximize storage capacity in a limited space with Mobile racking

The main goal that Customer set for ORION in their new warehouse project was to achieve maximum storage capacity without giving up direct access to the goods stored. This would mean that costs could be saved in terms of surface area for building, as well as achieving the greatest possible reduction in terms of volume required for goods storage.

ORION’s baseline plan was as follows:

New warehouse building of 481 ㎡, of 29.7 m long, 16.2m wide and 6.3m high;

Unit load: 1250kgs/pallet;

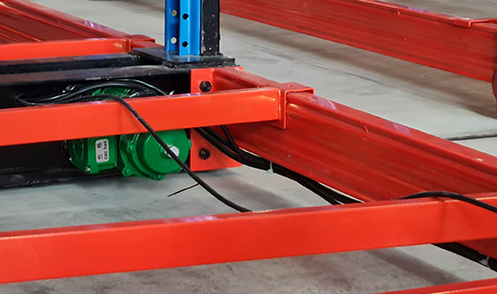

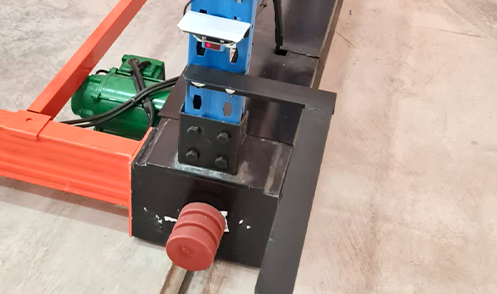

Safety: Install devices such as "emergency stop devices" and "infrared sensors" to enhance safety.

Since goods are stored in a compact position until the operator selects the aisle needed for work, and the racks open in a cascade formation, leaving just the necessary aisle open, just one aisle per block is needed to access goods. This means that this solution offers an extremely significant saving in terms of space and an increase in storage capacity of more than 50% when compared to an installation using conventional pallet racking.

| Length of racks: | 23.31 m |

| Height of racks: | 5.20 m |

| Number of Moving rack units: | 40 bases |

| Number of aisles: | 1 per block |

| Aisle width: | 3860 mm |

| Number of load levels: | 4(base+3) |

| Height of load levels: | 1200 mm |

| Number of racks: | 10 sets start rack , 80 sets connect rack |

| Warehouse temperature: | Normal temperature |

| Other products installed: | Conventional static pallet racking |

| Pallet size: | L1100*W1100*H150 mm |

| Total capacity of storage: | 720 pallets |