PRODUCT

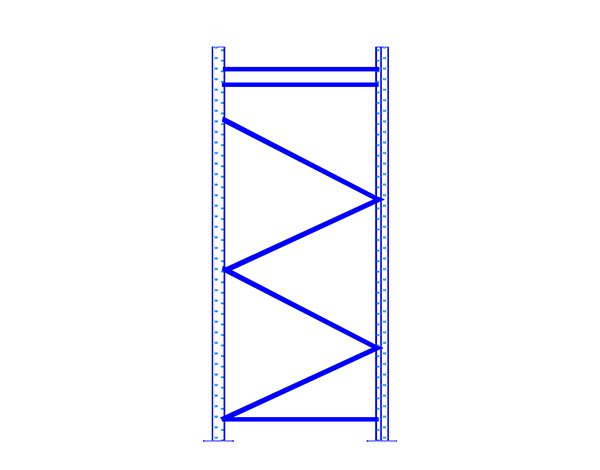

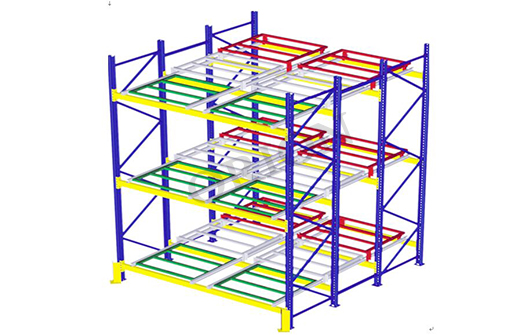

Gravity Flow Rack:

Gravity flow racks is a flexible storage system based on gravity tracks with an inclination of 3-5°.

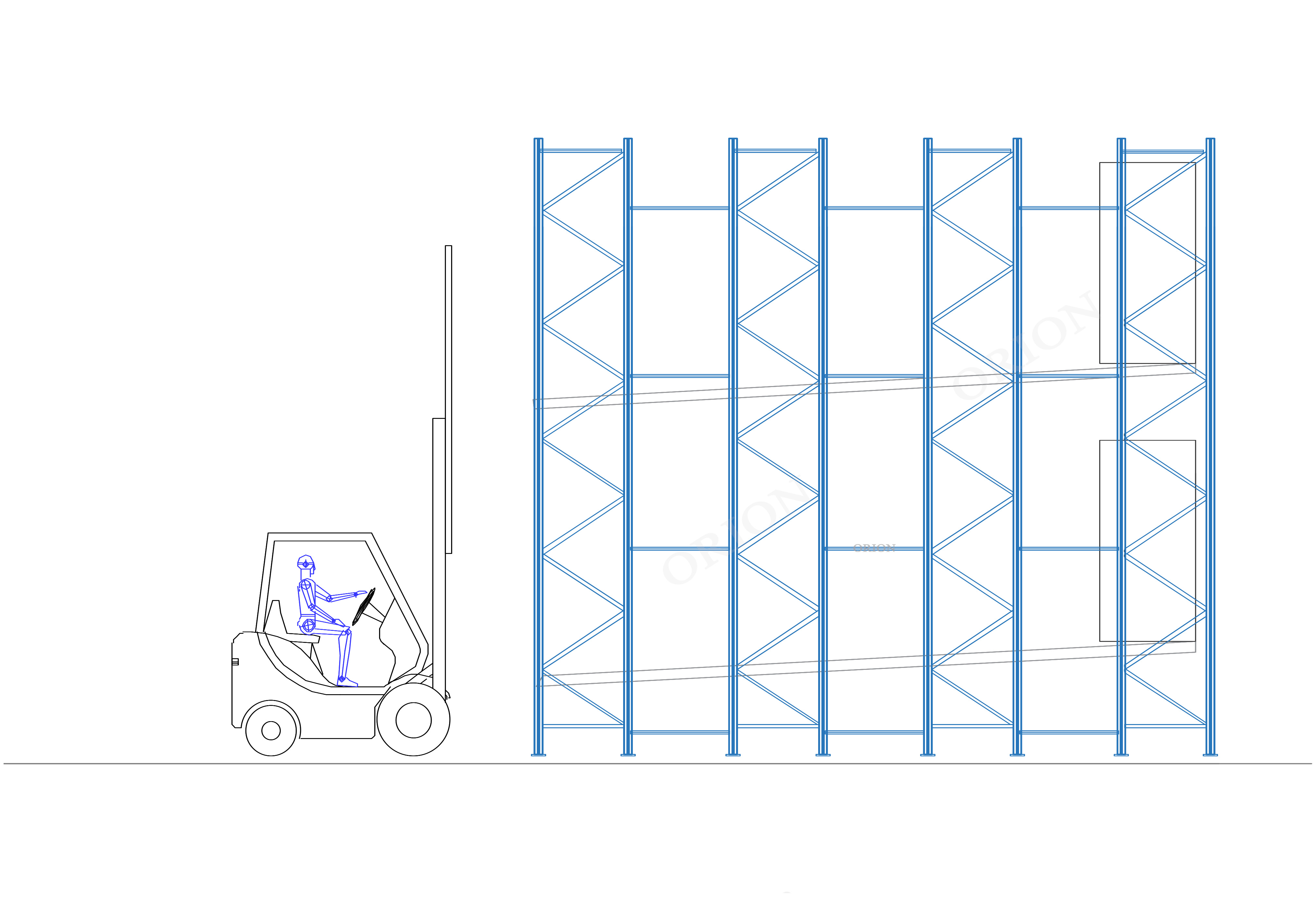

The goods are moved by gravity on the tracks. When the bottom product is removed, the subsequent goods will automatically slide to the bottom of the shelf.Compared with the flow through rack, gravity flow rack are suitable for storing and picking heavy goods ,using pallets to storage and forklifts to access, while flow through rack suitable for storage light-duty cargo. It is suitable for storage the large quantities and same type of goods.

The space utilization rate is very high, especially suitable for storing goods that have a certain warranty period and are not suitable for long-term backlogs.

ADVANTAGES OF GRAVITY FLOW RACK

- FIFO: When the goods are placed in the storage end by forklift truck, they will automatically slide under the action of gravity, to realize the automatic storage and removal of the goods;

- Efficient picking: Using the gravity of the goods and the slope design of the shelves, the automatic flow is realized, greatly improves the storage efficiency;

- Increased storage space: Reducing unnecessary aisles between racks can increase storage space up to 60%;

- No power device: Gravity flow rack does not require any power device, no energy consumption, no noise, safe and reliable.

GRAVITY FLOW RACK APPLICATIONS

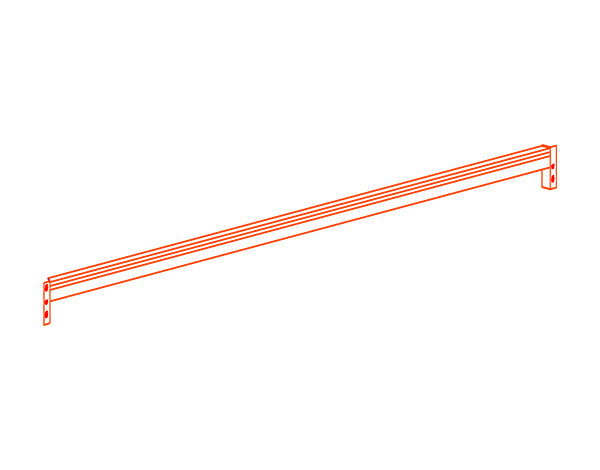

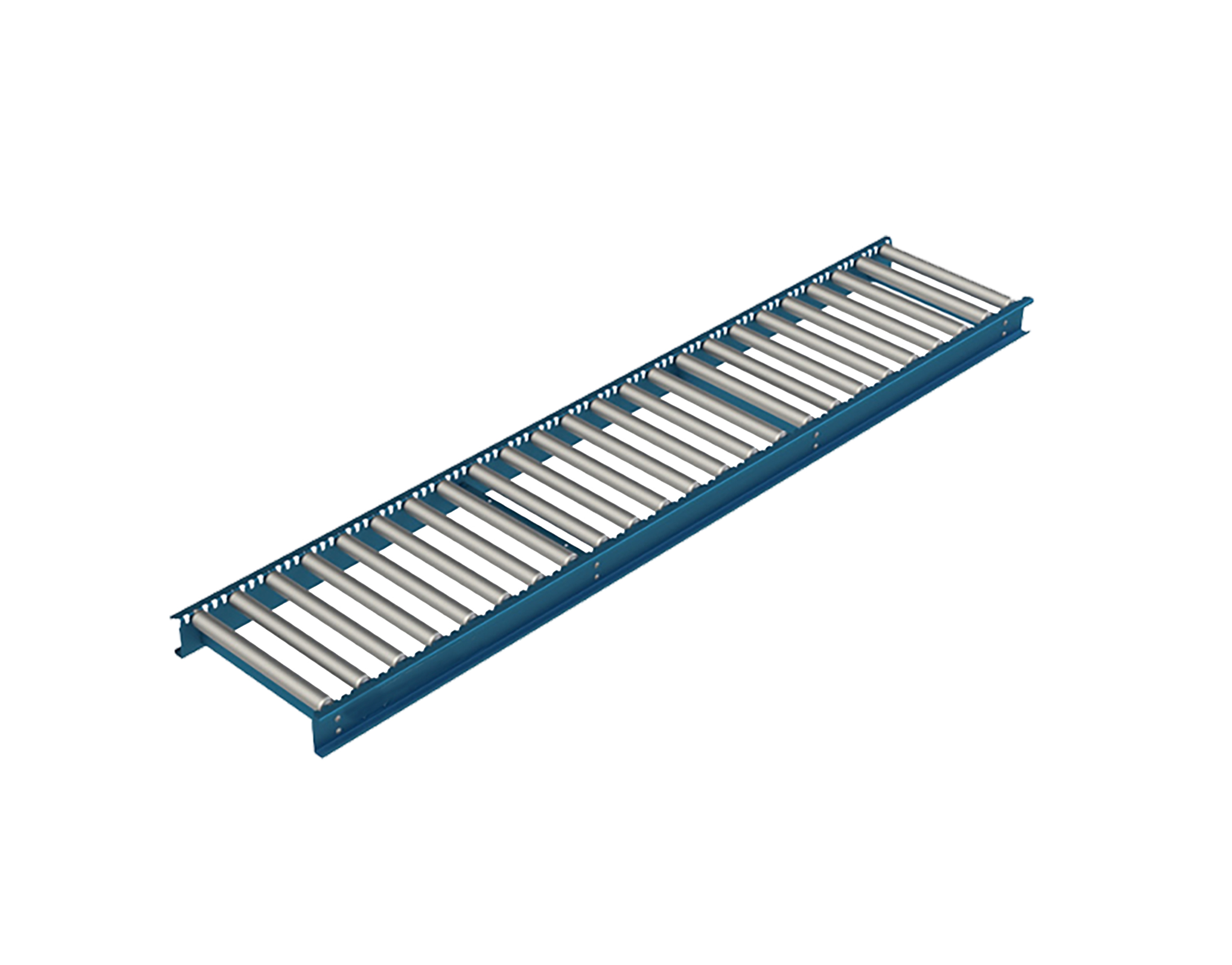

GRAVITY FLOW RACK ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

gravity flow rack is a storage shelf system that uses the gravity of the goods themselves to achieve IFO storage. Goods are placed on a roller with a certain slope through pallets or containers, and automatically glide from the incoming end to the outgoing end by gravity.

Food and beverage industry, pharmaceutical industry, electronic and electrical industry, logistics distribution center.

Efficient storage, FIFO, reduce labor intensity, good stability.

Regularly check the structural components of the shelf; Check the running condition of rollers and rollers to ensure smooth rolling; Store goods strictly according to the carrying capacity of the shelves.

The investment cost is high, the installation requirements are strict, the shape of the goods is limited, and the flexibility is limited.