PRODUCT

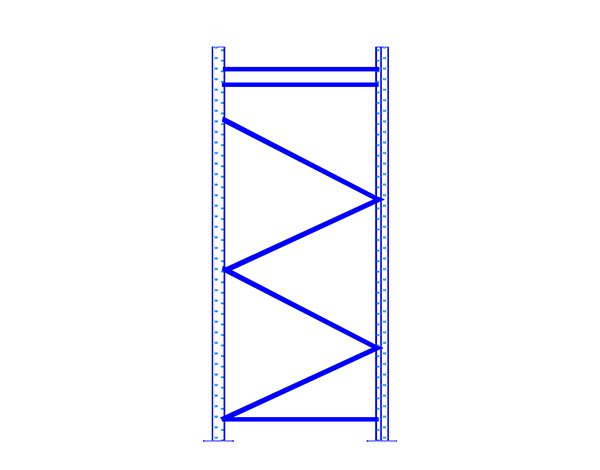

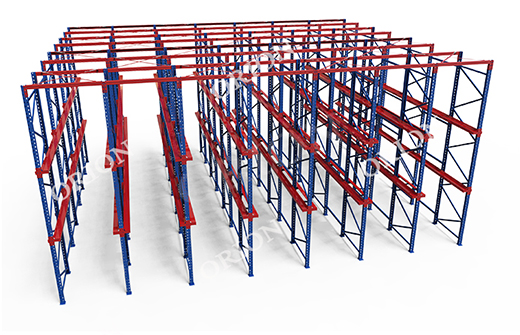

Pallet Racking:

It is the simplest and most effective diversified storage racking, where goods are placed on pallets and stored on the racks by forklift. It has the characteristics of flexible and fast access operation, strong selectivity, FIFO, and a high turnover rate.

The specification of the rack can be customized according to different spaces and goods. Due to its simple construction, versatility, easy assembly and low implementation cost, conventional pallet racking is the most commonly used storage system in warehouses.

DESIGN FACTOR

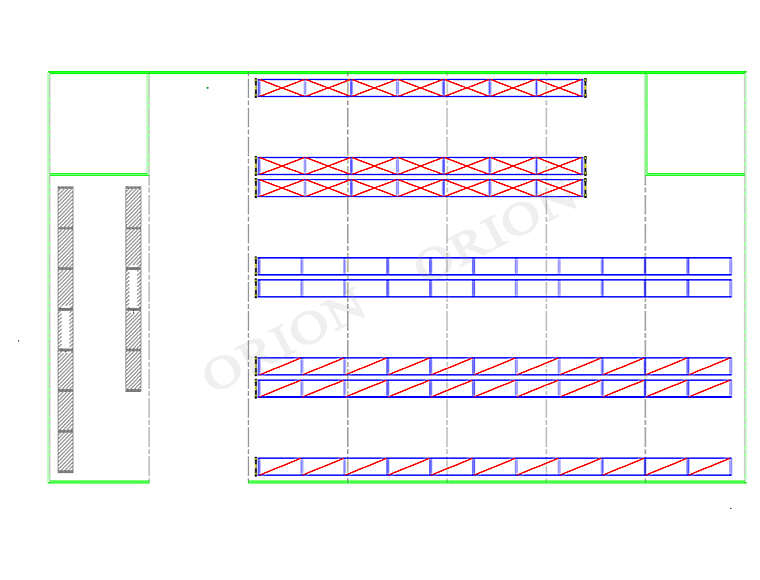

| Carrying capacity: | According to the Cargo weight to determine the bearing requirements of the shelf, and consider the safety factor; |

| Shelf size: | According to the size of the warehouse and goods to determine the shelf size. |

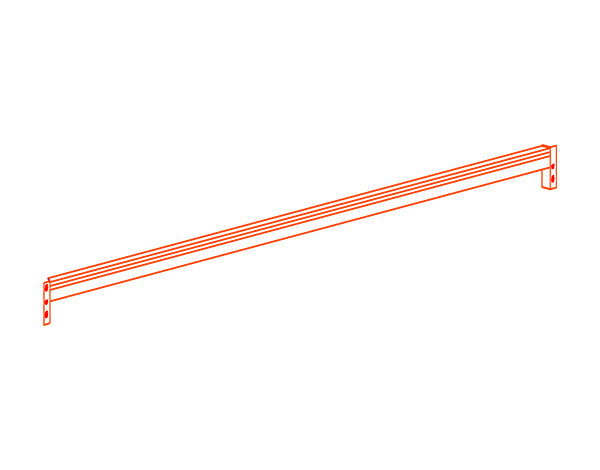

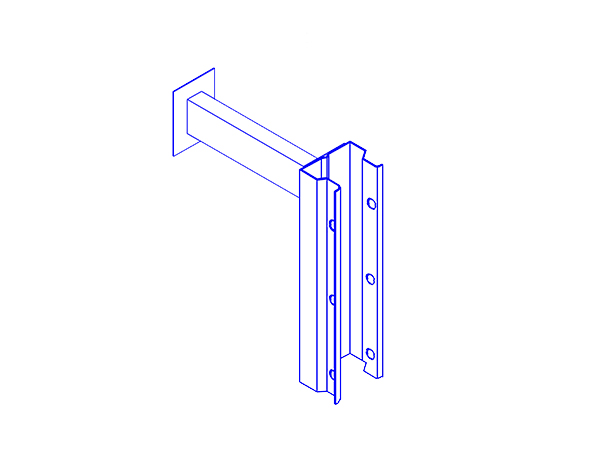

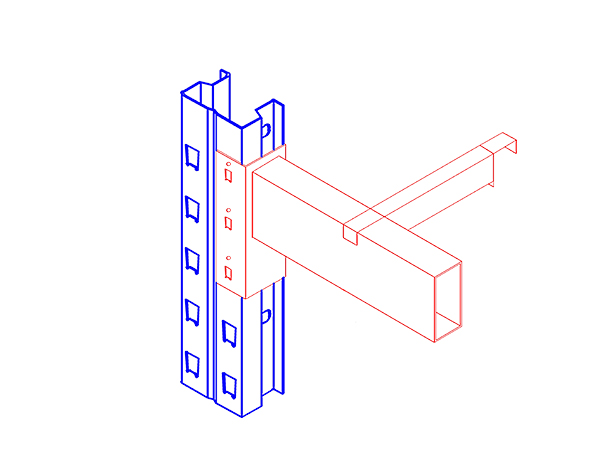

| Posts and beams: | Select the appropriate posts and beams according to the bearing requirements and shelf size. |

| Aisle: | Ensure that the aisle width meets the requirements for turning, lifting, and accessing the forklift. |

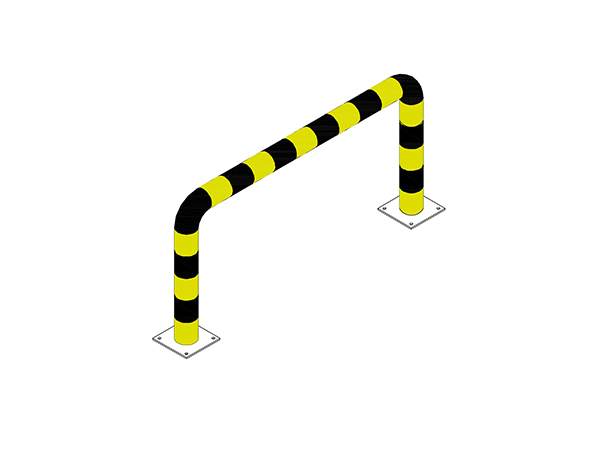

| Safety: | Install anti-collision guardrail or anti-collision column to prevent forklift collision and damage to the shelf. |

| Cost optimization | Select cost-effective materials and maximize the use of warehouse space. |

ADVANTAGES OF PALLET RACKING

- Direct access to each pallet: All pallets are accessible from the working aisle.

- Easy to disassemble: All composite structure, it is easy and fast to assembling, flexible application.

- Height adjustable: The spacing between the holes of the upright pitch is 50mm/75mm, and the layer spacing can be adjusted flexibly according to the height of the goods.

- Strong bearing capacity: The bearing capacity of the selective pallet rack is very good,the maximum load of each layer can reach 3T/ layer under the relative design.

- Structural design stability: Can resist the influence of a variety of external factors to ensure the safety of goods.

- Low cost: It can save costs for enterprises.

PALLET RACKING APPLICATIONS

Pallet rack have a wide range of application values in different scenarios and industries, and can provide enterprises with efficient and safe storage management solutions.

PALLET RACKING ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Pallet rack is a common storage shelf, mainly composed of posts and beams. Suitable for the storage of pallets.

Manufacturing, logistics and warehousing, retail and wholesale, cold chain logistics, etc.

The load capacity depends on the post and beam specifications, usually 1000-3000kg.

Depending on the model of the forklift and the turning radius, it is usually 2.5-3.5m.

The maximum height is usually subject to the clearance height of the warehouse and the lifting height of the forklift, which can generally reach 10-12 meters.

Simple structure, easy to install; Direct access to each pallet; Low cost and high flexibility, a wide range of applications.

Compared with automated shelves, the access efficiency is low, relying on manual or forklift operation; Space utilization is limited.