PRODUCT

AS/RS SYSTEM:

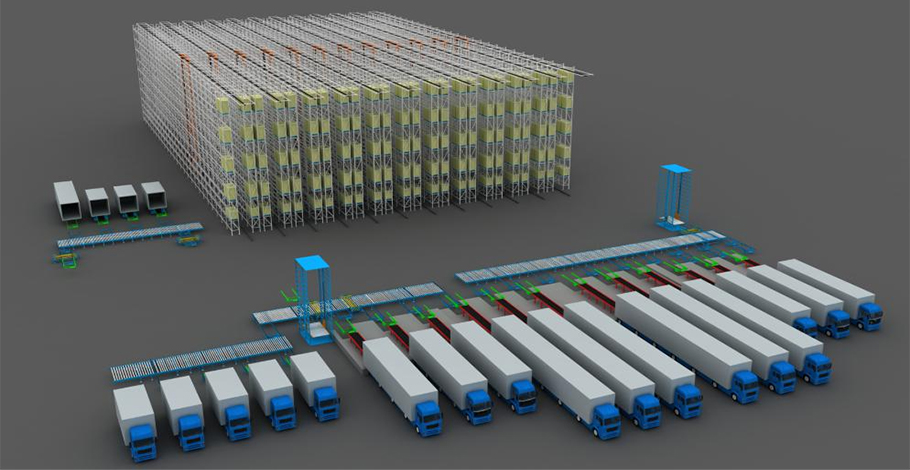

AS/RS systems are designed for automated storage and retrieval of parts and items in manufacturing, distribution, retail, wholesale and institutions.

Adopt the equipment such as lane stacker, inlet and outlet conveyor, apply the advanced automation system hardware equipment and software products to automatically realize the continuous transmission of goods, data storage management and inlet and outlet management. It has the characteristics of improving the level of warehouse automation and management, and improving the efficiency of logistics.

ADVANTAGES OF AS/RS SYSTEM

- Improve space utilization: High-rise shelf storage, save floor space, improve space utilization;

- Improve efficiency: Access, running speed;

- Reduce inventory accumulation: The system allows you to control inventory levels and maximize the use of warehouse space;

- Reduce expenses: AS/RS system help companies cut expenses by improving organization of the contents of a warehouse and reducing labor costs.

AS/RS SYSTEM APPLICATIONS

The automated warehouse AS/RS system is widely used in almost all industries.

The main industries of application are machinery, metallurgy, chemical, aerospace, electronics, medicine, books, food processing, tobacco, printing, distribution centers, airports, ports, etc.

FAQS

AS/RS is the automatic storage and retrieval system, which integrates advanced automation technology, information technology and warehousing logistics concept, can realize the automatic storage, retrieval and warehousing operation of goods, and greatly improve the storage efficiency and management level.

It is widely used. It is applicable in the e-commerce industry, the pharmaceutical industry, the automobile manufacturing industry and the cold chain logistics field.

In terms of space utilization,AS/RS system can make full use of the vertical space, and the storage density is much higher than the traditional shelf. In terms of efficiency, the efficiency of storage and input is greatly improved. In terms of accuracy, the system is accurately controlled by the computer, and the accuracy of cargo storage and retrieval is higher.

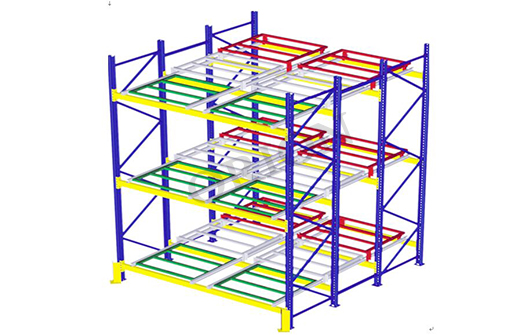

It is mainly composed of shelves, stackers, conveyor systems, control systems and other parts.

With the help of advanced inventory management software, the system is integrated with enterprise ERP system. When the goods are stored, the information and storage location of the goods are automatically recorded; When out of the warehouse, according to the order information to accurately retrieve and transfer the goods. Update inventory data in real time throughout the process, effectively avoid inventory overstock or out of stock, and achieve accurate inventory management.

The installation is complicated, involving shelf construction, equipment installation and commissioning, and system integration, requiring professional teams to work and follow strict installation procedures and quality standards to ensure stable operation of the system.

Due to the high degree of equipment automation and complex technology, the maintenance cost is relatively high compared with traditional shelves.