PRODUCT

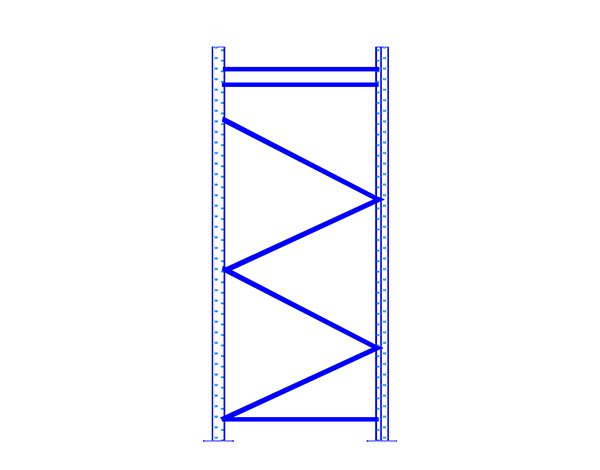

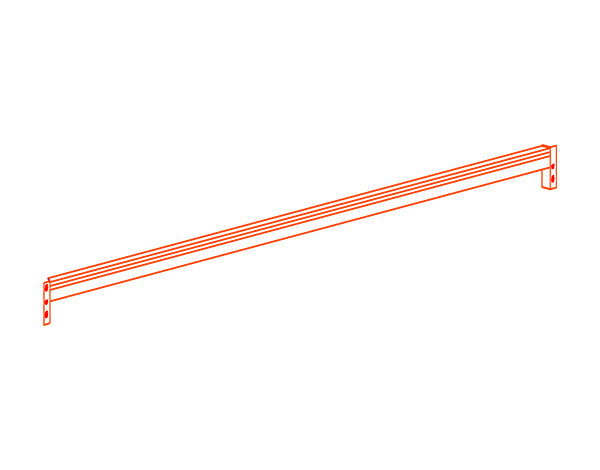

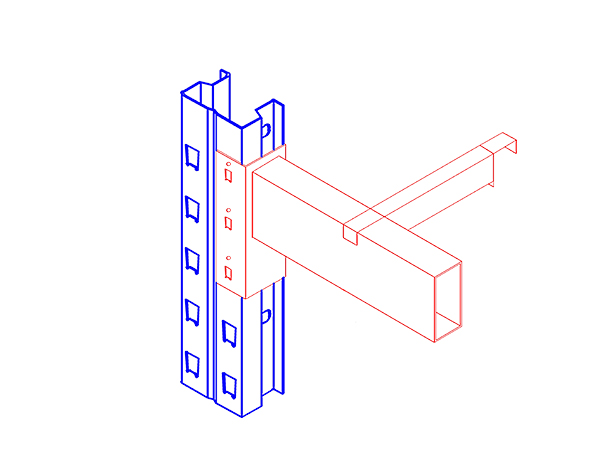

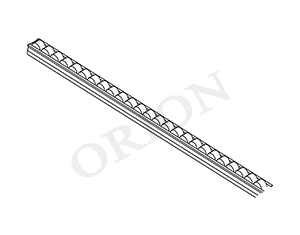

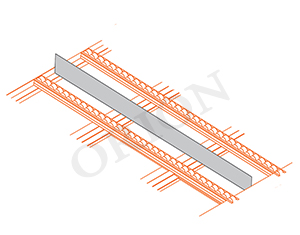

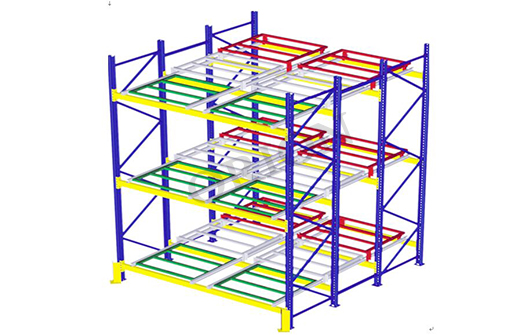

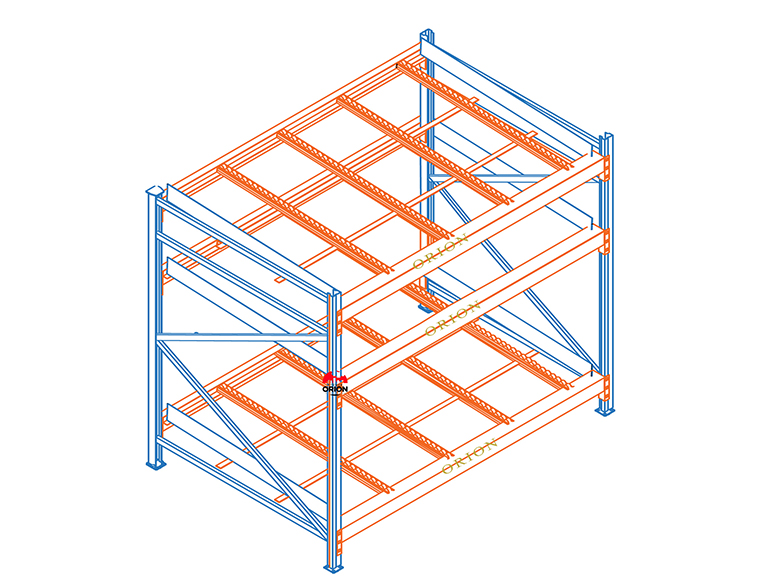

Flow Through Rack:Flow through rack is combination of fully combined rack and roller-type fluent strips.The fluent strips can be adjusted, the standard is about 3-5 degrees, the goods are put into the back of the shelf, the front is taken out, the goods slide downward relying on their own gravity, to ensure that the goods are stored in accordance with the first-in-first-out order.

Easy access, save space, improve efficiency.

DESIGN FACTOR

| Cargo characteristics | Determine the load bearing and size of the shelf. |

| Tilt angle | Adjust the slope according to the weight of the cargo. |

| Storage requirements | Determine the number of shelves and layers |

| Space utilization | Make full use of vertical space and rationally plan the aisle and shelf arrangement. |

| Access mode | FIFO,ensures sequential access to goods. |

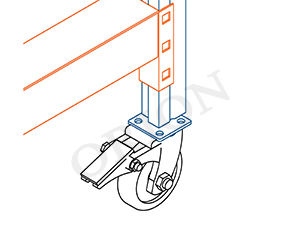

| Safety | Ensure the shelf load bearing and seismic capacity; Install guardrail and anti-slip device. |

| Modular design | Support late expansion, adapt to changes in warehouse layout. |

ADVANTAGES OF FLOW THROUGH RACK

- FIFO: It not only improve the inventory turnover, but also effectively avoid the problem of overstocking and expiration of goods;

- High-density storage system: Reduce the number of channels, space utilization rate than traditional shelves increased by 30%-50%;

- Efficient and convenient: Goods automatically slide to the shipping end, reduce manual handling time, improve sorting efficiency;

- Comfortable working environment: The fluent strip is made of high-quality materials, good rolling performance, low noise, providing a more comfortable working environment for operators;

- Informatization management: It can be equipped with electronic labels to realize the information management of goods.

FLOW THROUGH RACK APPLICATIONS

FLOW THROUGH RACK ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Use the weight of goods to realize the automatic slide of goods with the help of rollers and other devices. It is usually installed at a certain slope, the goods are stored at the front of the shelf, and the backward end is slid under the action of gravity, which facilitates the FIFO cargo access mode.

FIFO, efficient storage, reduce labor intensity, good stability, adjustable.

Distribution center, production line, pharmaceutical industry, etc.

The ground is smooth; Set slope reasonably; The fluent strip is installed firmly and parallel, and the spacing is uniform; dividers height is moderate.

The tilt angle needs to be determined according to the weight of the cargo and the sliding speed, usually 3°to 5°. The tilt angle of heavy cargo is small (3°-5°), and the tilt angle of light cargo is large (5°-7°).

Install a buffer device, add anti-slip measures, install a stopper to control the sliding range of goods.

There are shape and weight restrictions on the goods stored; Cost and maintenance costs are higher than ordinary shelves; The spatial layout is not flexible.