PRODUCT

Mobile Rack:

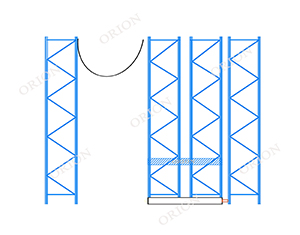

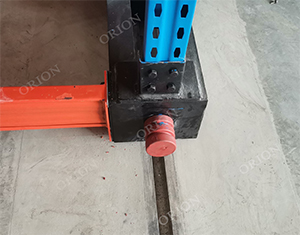

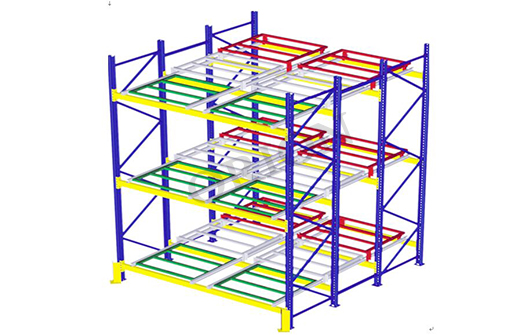

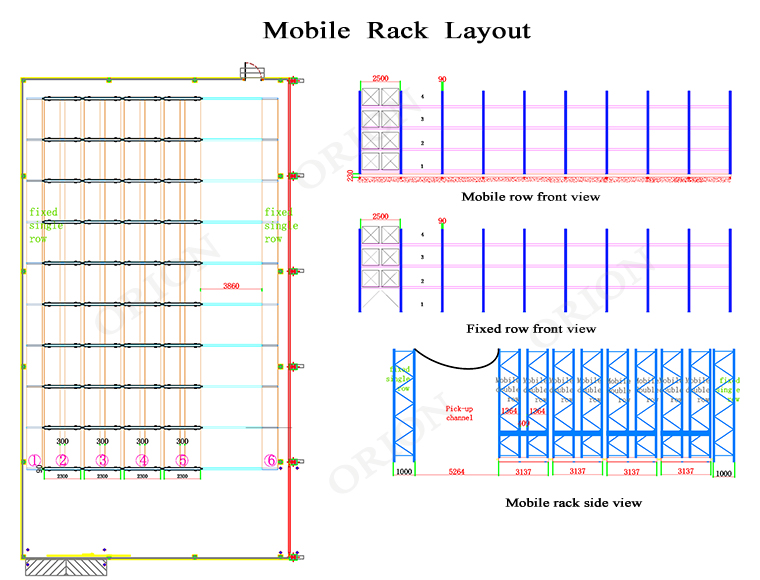

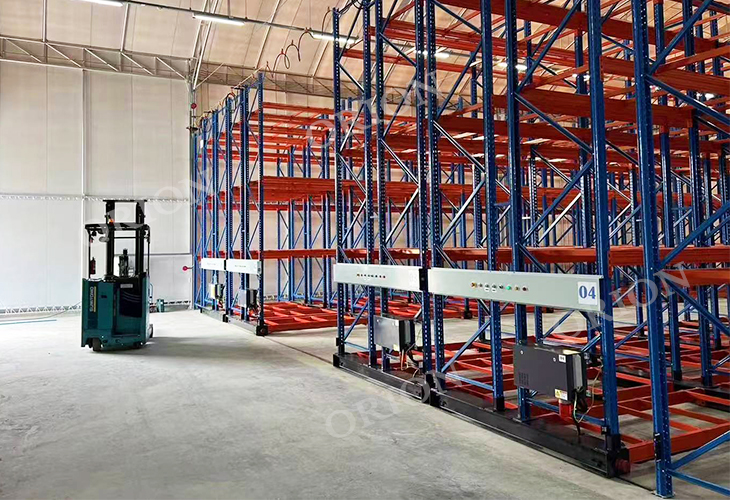

The mobile rack is derived from the pallet rack,two rows of racks are mounted back to back on a mobile base, arranged in a number of groups, each base is equipped with a roller and motor, by pressing the control button, the racks move along the track laid on the ground. Thus, the forklift can enter the channel to access the goods.

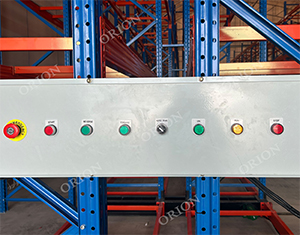

The shelf system is equipped with a number of infrared sensors, when the shelf in the process of moving, there are personnel or forklift into the channel, the shelf will automatically stop.

It only needs one channel, high space utilization, safe and reliable, easy to move.

Suitable for many varieties, but access frequency is low warehouse.

DESIGN FACTOR

| Space layout | According to the warehouse area to determine the layout and number of mobile shelves, make full use of space. |

| Load capacity | According to the weight of the goods to design the shelf’s load-capacity, including the load of each layer and the total load of the entire shelf. |

| Channel width | The channel width should meet the traffic requirements of handling equipment and goods size, but also make full use of warehouse space. |

| Length design | With the increase of shelf length, its stability will be affected to a certain extent. It is necessary to consider the warehouse space and also the stability of the shelves. |

| Mobility | Select the right mode of movement and drive. The common moving methods are manual, electric and so on. |

| Stability | In order to prevent the shelf from tilting during movement, stability measures need to be taken. |

| Safety | Not only to consider the safety of the shelf structure, but also to consider the personnel and goods. Set infrared sensor, set emergency stop button, etc. |

ADVANTAGES OF MOBILE RACKING

- Direct access: Each pallet can be accessed by moving shelves;

- High space utilization: There is only one channel, and other Spaces can be placed shelves to improve storage;

- Good safety: Multiple infrared sensors and Emergency stop are installed to ensure the safety of personnel in the operation of the shelf.

- Environmental protection and energy saving: Due to the reduction in the number of channels, the coverage area of facilities such as warehouse lighting and air conditioning is reduced, thus reducing energy consumption.

MOBILE PALLET RACKING APPLICATIONS

MOBILE PALLET RACKING ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.FAQS

Mobile shelf is a storage device that can be moved on a track. It consists of shelf, track and drive system.

There are two main types: manual and electric. Manual operation is suitable for light cargo. Electric drive with motor and control system, suitable for large warehouses, high frequency of use scenarios.

Mobile shelves through manual or electric drive, slide on the track, so that the multiple channels between the original multiple rows of shelves, into only one channel can access all the goods, greatly improving the space utilization rate.

Check the flatness of the warehouse ground to ensure that it meets the installation conditions; Install the track, accurately calibrate the levelness; Main shelf installation; Install and debug the drive system; Final overall inspection.

High space utilization, flexibility, storage security.

The initial investment cost is high; the ground requirements are high,;the maintenance requirements are many;and the spatial layout flexibility is limited.

Warehousing and logistics industry, manufacturing industry, electronic and electrical industry, etc.