PRODUCT

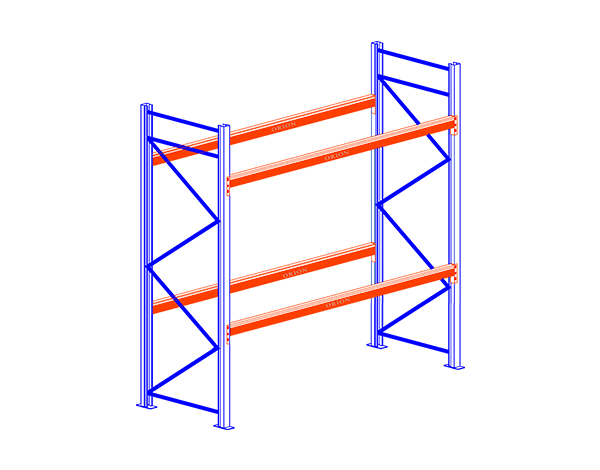

Mezzanine rack

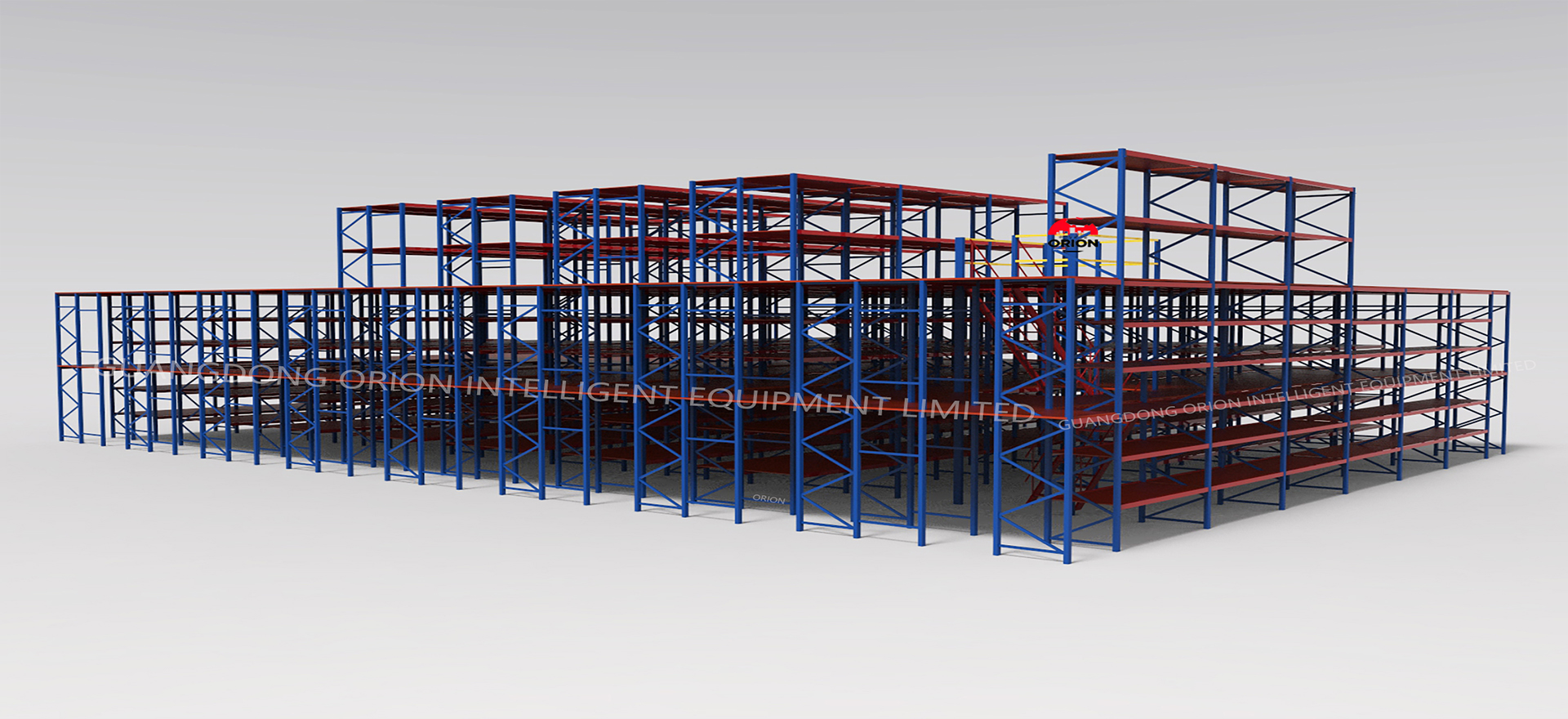

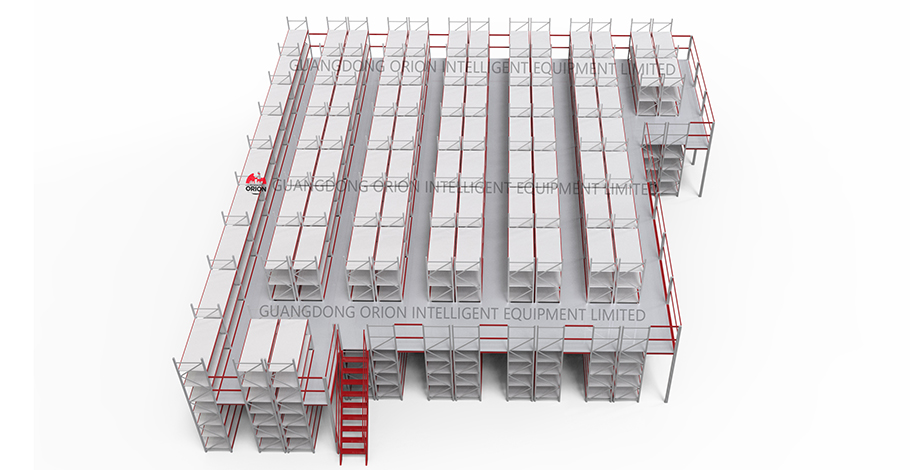

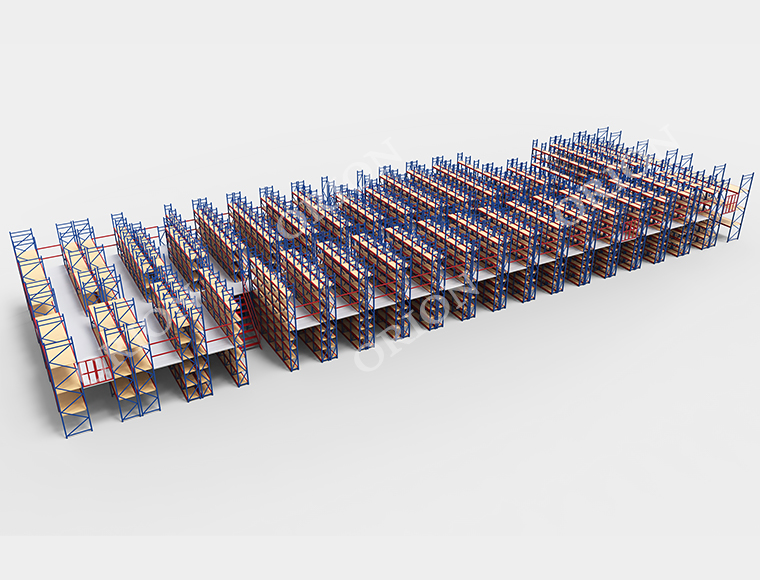

Mezzanine rack is a racking system that build a middle attic on an existing workspace or shelf to increase storage space. Usually use medium or heavy duty shelves as the main support, plus floor panels can be made two or three floors. It is appropriate to access some light goods, suitable for multi-variety and manual access of goods.

The goods are usually sent to the second or third floors by forklifts, hydraulic lifting platforms or freight elevators, and then sent to a certain location by light cars or hydraulic pallet trucks.

DESIGN FACTOR

| Warehouse space | According to the actual height of the warehouse to determine the number of floors and the height of each floor. |

| Cargo characteristics | According to the weight of the goods, size and category to determine the load-capacity of each layer and shelf size. |

| Access mode | Design shelf height and channel width according to manual access or mechanical equipment access. |

| Load-capacity | According to the weight of the goods and storage mode, design a reasonable shelf structure. |

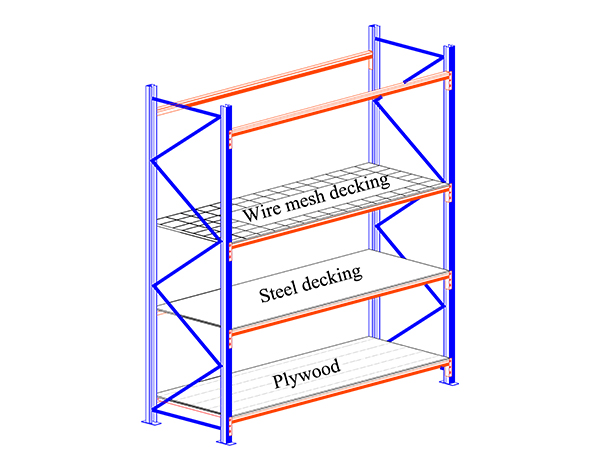

| Floor selection | The floor according to the need to choose the appropriate plate, the common pattern steel plate, grid plate, plywood. |

| Fire and safety | Set up reasonable fire facilities, safety passages, protective devices. |

ADVANTAGES OF MEZZANINE RACK

- Make full use of space:Mezzanine rack can improve the shelf height and make better use of storage use;

- Easy to disassemble:All composite structure, it is easy and fast to assembling, flexible application;

- Flexible and changeable: Different choices of laminates to meet the different requirements of ventilation, fire prevention, lighting and so on. Cargo elevator, lifting platform, forklift can be selected for the cargo on and off the floor;

- Economical:Mezzanine rack is a more economical solution than new warehouses.

MEZZANINE RACK APPLICATIONS

Mezzanine rack are widely used in the case of higher warehouse, smaller goods, manual access, and larger storage capacity, which can make full use of space and save the warehouse area.

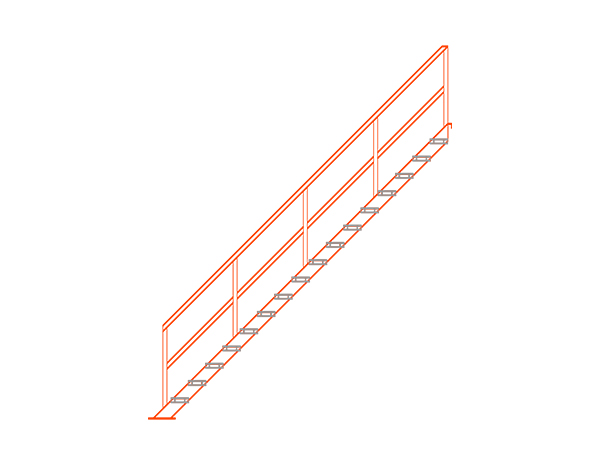

MEZZANINE RACK ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Mezzanine rack are multi-layer structures, usually using the upper space of the warehouse, by building a steel structure platform to form a loft-like multi-layer storage area.

The e-commerce industry is used for commodity storage and sorting; Machinery manufacturing industry storage parts, tools, etc.; Electronic industry storage of electronic components and finished products; Warehousing logistics industry to achieve goods transfer and distribution storage

Mainly depends on the height of the warehouse. If the height of the warehouse is 5-9 meters, it is usually suitable for designing two layers; More than 9 meters, can consider three layers and above.

The layer spacing is generally 2.2-2.7 meters, which is convenient for personnel to operate. The specific adjustment depends on the actual height of the warehouse, the characteristics of the goods and the mode of operation.

Constant load (shelf and floor weight) and live load (cargo, personnel, equipment weight) should be considered.

The most prominent advantage is to maximize the use of vertical space, in the limited plane area of the warehouse, by building multi-layer storage area, greatly improve the storage density, reduce the unit storage cost.

The efficiency of cargo handling is low, not conducive to large-scale mechanized operations and poor flexibility.