PRODUCT

Very Narrow Aisle Racking:

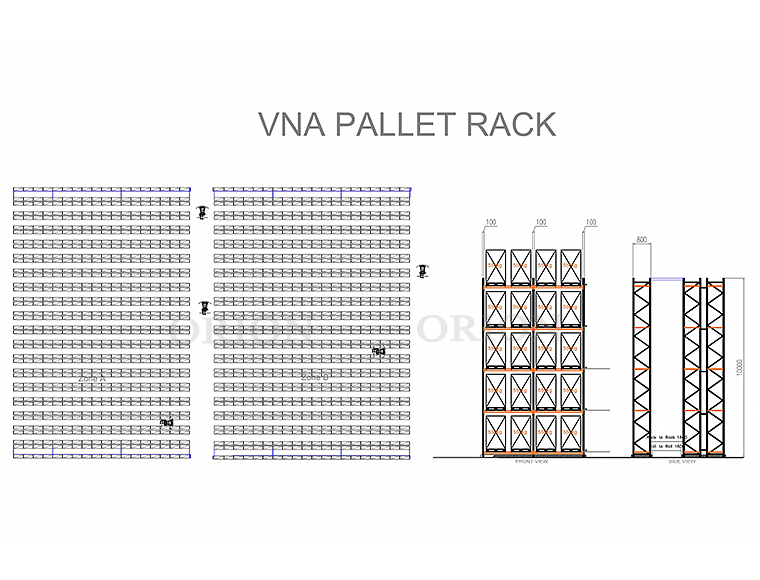

The core feature of VNA rack is that the channel width is narrow, usually between 1600mm and 2000mm. The VNA rack not only has a high storage density, but also all the stored materials are 100% optional, and the forklift can store or extract any pallet goods at any time.

This makes it very suitable for warehouses with frequent entry and exit of goods and high sorting requirements for goods.

DESIGN FACTOR

| Warehouse space planning | According to the warehouse clearance height to determine the total height of the shelves, make full use of vertical space. |

| Cargo characteristics | Cargo size, weight and access frequency. |

| Bearing capacity design | According to the weight of the stored goods to determine the bearing requirements of the shelf, and consider the safety factor. |

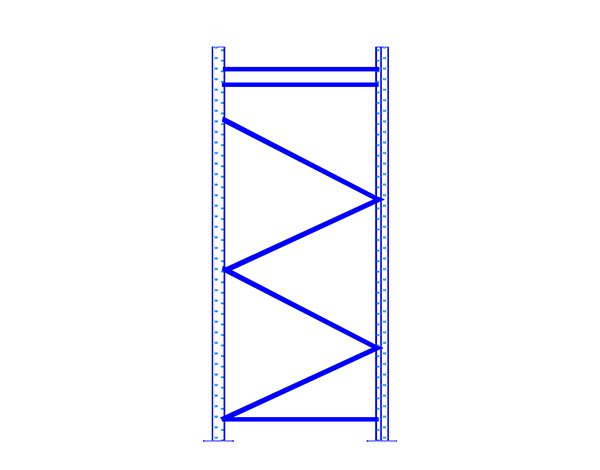

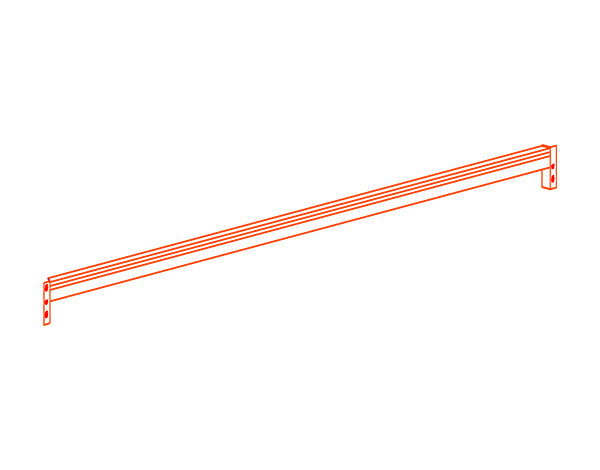

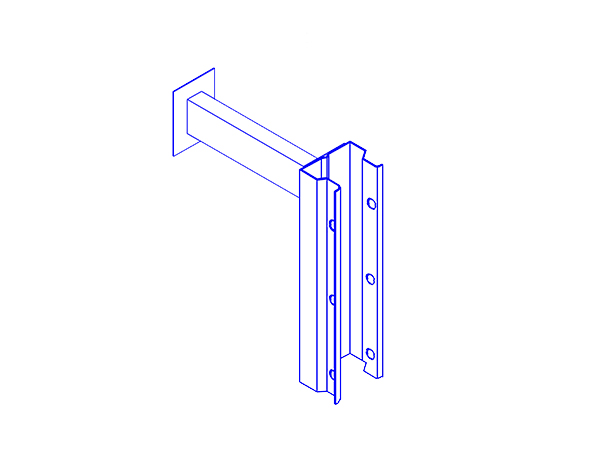

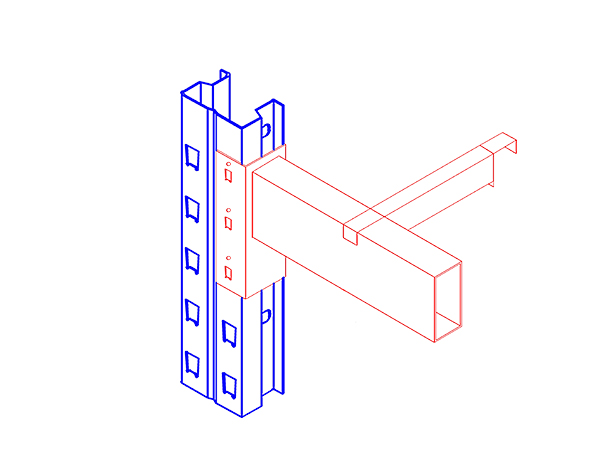

| Shelf structure design | Determine the specifications of posts and beams according to the load bearing. |

| Channel design | Ensure that the channel width can meet the operation requirements of the forklift,usually 1.6-2.0m. |

| Forklift selection | Select forklifts suitable for narrow roadway operation, such as three-way forklifts or rotary forklifts. |

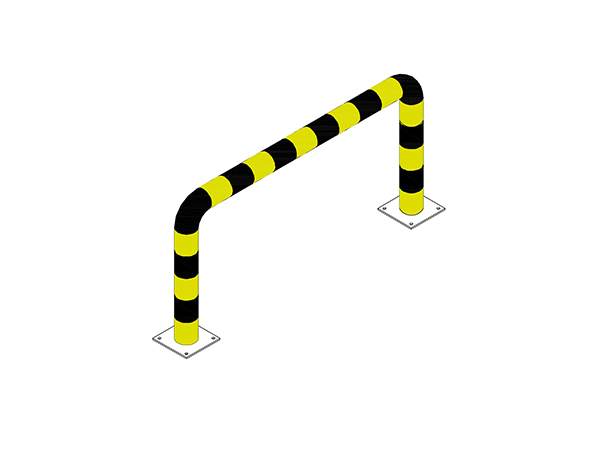

| Safety design | Install post protectors or frame protectors at the bottom of the shelf to prevent forklift collision and damage the shelf. |

| Expansion | Modular design is used to facilitate later expansion or adjustment of shelf layout. |

ADVANTAGES OF VERY NARROW-AISLE RACK

- Direct access: VNA rack allow direct access to all goods, reducing preparation time;

- High storage density: Increases storage density in warehouses by reducing aisle widths and storing goods in compact spaces. The channel is usually between 1600mm and 2000mm;

- High picking efficiency: The use of three-way stacking forklift to access the cargo, this forklift can operate flexibly in narrow channels, greatly improving the picking efficiency;

- Safety: Equipped with anti-collision device to ensure the safe storage of goods and the safety of the picking process.

VERY NARROW-AISLE RACK APPLICATIONS

Suitable for industries that require direct access to goods and save space.

VERY NARROW-AISLE RACK ACCESSORIES

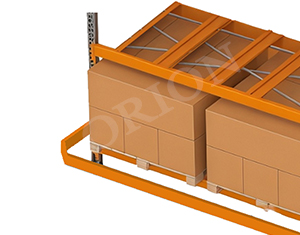

The main structure of the VNA rack is similar to the pallet rack.

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

VNA is a high-density storage system that maximizes warehouse space by reducing aisle width. It needs to cooperate with a special narrow tunnel forklift for access operation, suitable for storing large quantities of goods with few varieties.

High space utilization, high storage efficiency, stable shelf structure, strong carrying capacity.

Food and beverage industry, pharmaceutical industry, electronic and electrical industry.

VNA have higher requirements for warehouses, including warehouse height, ground smoothness, channel width, forklift selection, warehouse layout, environmental conditions, safety measures and maintenance management. Through scientific and reasonable design and management, the advantages of narrow lane shelves can be maximized to improve storage efficiency and safety.

The width of the channel depends on the model of the forklift and the turning radius, which is usually 1.6-2.0 meters. Ensure that the channel width can meet the operation requirements of forklift trucks.

The maximum height of the VNA is usually limited by the clearance height of the warehouse and the operating height of the forklift truck, which can generally reach 10-12 meters. When designing, ensure that the shelf height matches the operating height of the forklift.

The safety can be guaranteed in a variety of ways, including reasonable design of shelf structure, equipped with safety protection devices, selection of appropriate storage equipment, standardization of personnel operation process and regular maintenance inspections.

The initial construction cost is high, the requirements for the warehouse ground bearing capacity are high, and the requirements for personnel operation are high.