PRODUCT

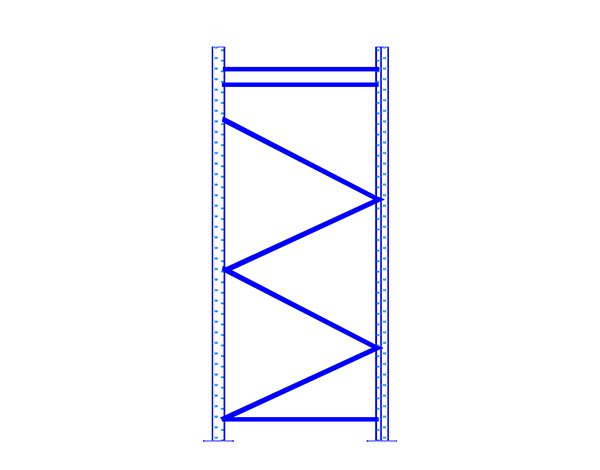

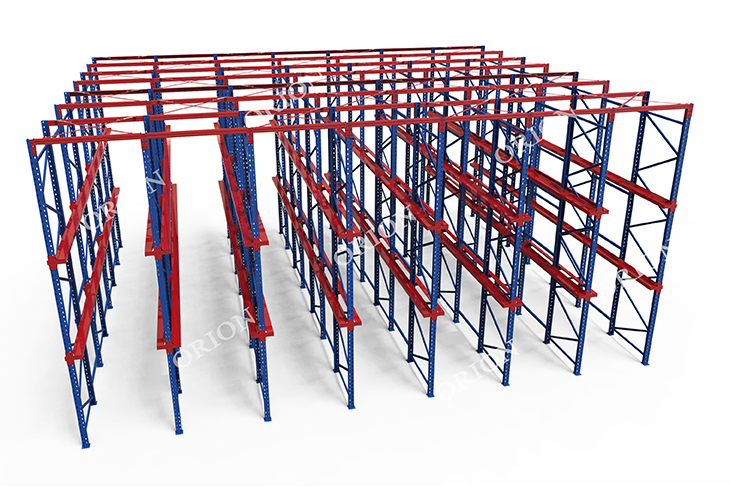

Drive-in/Drive-through Racking:

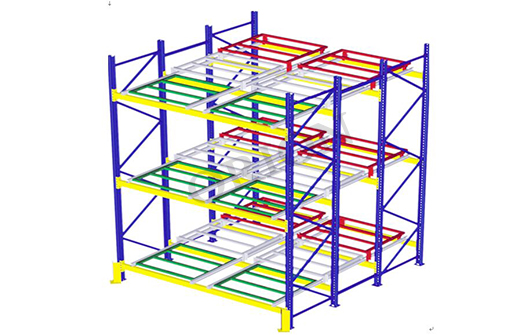

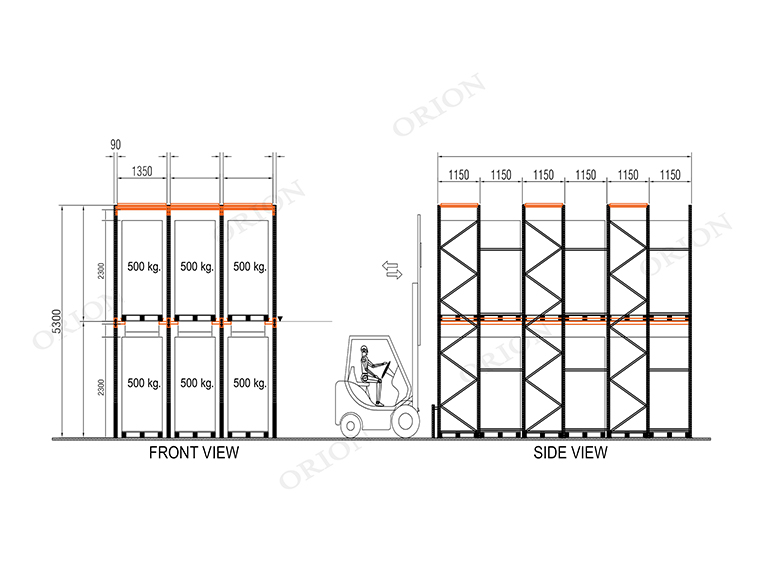

It is a continuous rack without channel segmentation; Compared with pallet racks, the warehouse utilization rate can reach about 80%, and the warehouse utilization space rate can be increased by more than 30%, which is the highest storage efficiency of the shelves.

On the support rails, pallets are stored in the direction of depth, one after the other. It is often used to store large quantities of the same type of goods.

DESIGN FACTOR

| Warehouse space planning: | Warehouse height, ground load bearing, fire passage; |

| Cargo characteristics: | Cargo size, weight and access frequency; |

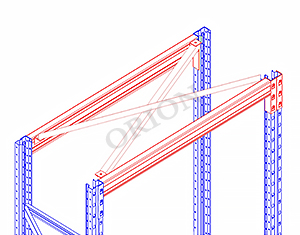

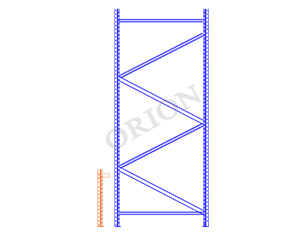

| Shelf structure design: | Post, beam and guide rail; |

| Channel design: | Channel width and direction; |

| Access mode design: | FIFO or FILO; |

| Bearing capacity design: | According to the weight of the goods to determine the bearing demand of the shelf and consider the safety factor; |

| Safety design: | Anti-collision measures and seismic design; |

| Modular design: | Modular structure is used to facilitate later expansion or adjustment of shelf layout; |

| Cost optimization: | Select cost-effective materials and maximize warehouse space. |

ADVANTAGES OF DRIVE-IN/DRIVE-THROUGH RACKING

- Less type, more quantity: The drive-in rack is suitable for storing the same type of goods with few varieties and large batches;

- High space utilization rate: The space utilization rate can reach 80%;

- Enter the aisles: The forklift enters the aisle of the racks to access the goods;

- Access method: Generally, goods are stored and retrieved based on the principle of FILO. However, through some special designs and management methods, the first-in, first-out principle can also be achieved.

- Low cost: The investment cost is relatively low;

- This kind of shelf should not be too high, generally within 10m, in addition to the system also need to add top spine bracing.

DRIVE-IN/DRIVE-THROUGH RACKING APPLICATIONS

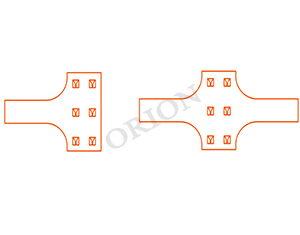

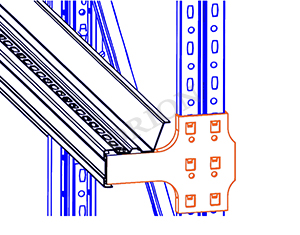

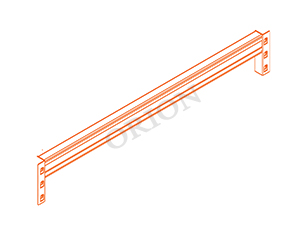

DRIVE-IN/DRIVE-THROUGH RACKING ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Drive-in rack is a high-density storage system that allows forklifts to drive directly into the aisle to access goods. It maximizes the use of warehouse space by reducing the number of channel.

It is mainly composed of upright frame, beam, corbel and track. The upright frame is supporting structure; The beam is connected with the upright frame through the corbel to form a platform for carrying goods; The track is mounted on shelf structure to guide the forklift.

It is suitable for less variety, more quantity cargo storage in food, beverage, tobacco and other industries, as well as scenes with high space utilization requirements such as e-commerce and logistics distribution centers.

In order to ensure the stability of drive-in rack, post protectors are set at both ends of the shelves to prevent forklifts from entering excessively; Cross rods are arranged on the side and the top to enhance the overall rigidity and stability of the shelf.

The width of the channel depends on the model of the forklift and the turning radius, which is usually 2.7-3.3 meters. Ensure that the channel width can meet the operation requirements of forklift trucks.

Counter balance forklift, reach lift truck and narrow channel forklifts are all available for drive-in rack operations.

Its biggest advantage is that the space utilization rate is extremely high, in the same warehouse area, compared with the pallet racks to increase the storage density of 30%-50%.

Forklift operation requirements are high; As forklifts frequently enter the interior of the shelves, the structure is vulnerable to damage.