PRODUCT

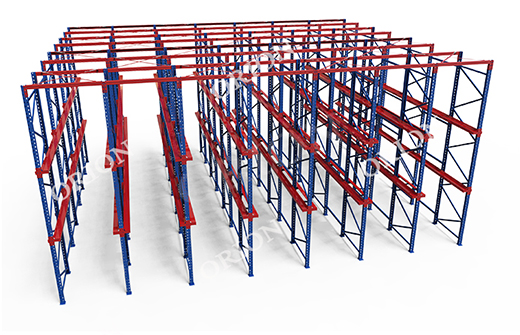

Radio-shuttle Racking:

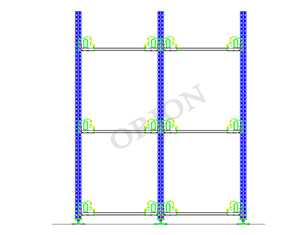

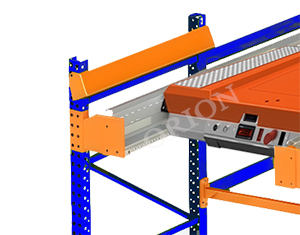

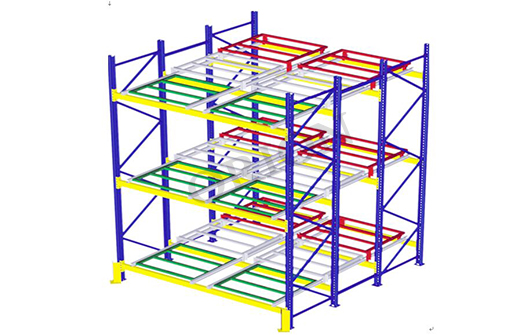

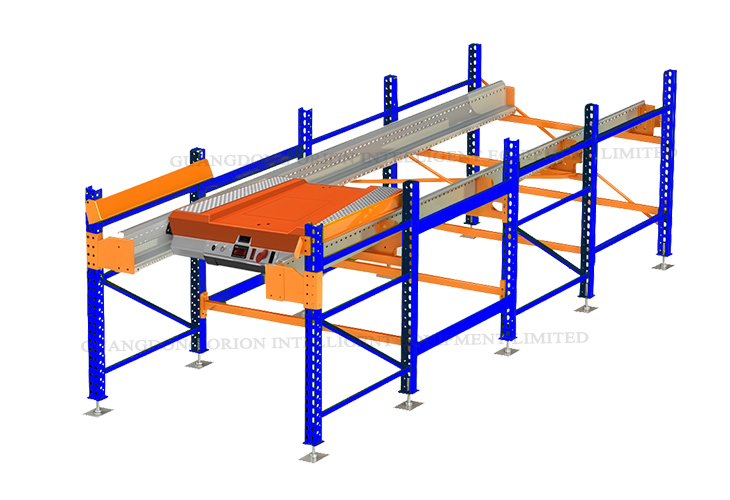

The Radio shuttle rack consists of three parts: racks, shuttle , and forklifts.It is a high-density pallet storage system that relies on the shuttle to stack goods in the rack rails.

The forklift puts the goods on the front end of the shelf guide rail, and the shuttle operated by remote control can carry the pallet on the guide rail. The shuttle can be placed in different lanes by forklift.The number of shuttle is determined by the depth of the roadway, the total amount of goods, the shipment volume, the shipment frequency and other comprehensive factors.

Compared with the drive-in rack, it has a high safety factor; Compared with the pallet rack, due to the reduction of forklift operation channel, truly achieve dense storage.

DESIGN FACTOR

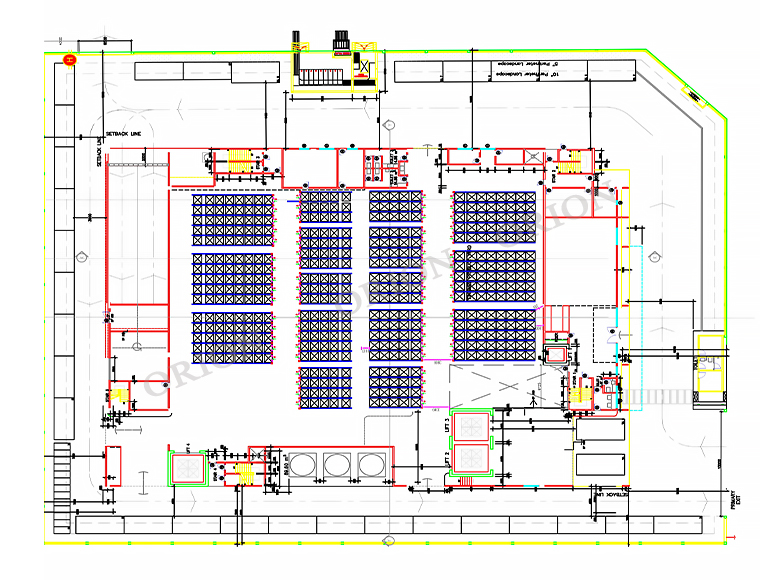

| Warehouse space planning: | Warehouse height, ground load bearing, fire passage; |

| Cargo characteristics: | Cargo size, weight and access frequency; |

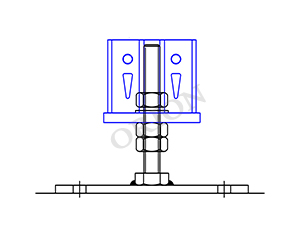

| Shelf structure: | Design posts, beams and tracks according to load-bearing requirements and overall stability; |

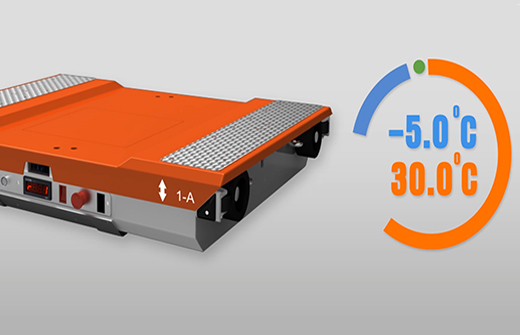

| Shuttle selection: | It is necessary to consider the carrying capacity, running speed, battery life and so on; |

| Access mode: | FIFO or FILO; |

| Channel: | Determine the channel width and direction; |

| Safety: | Collision prevention measures, emergency stop, seismic design; |

| System integration: | Integrated with the WMS to achieve intelligent management; |

| Cost optimization: | Reduce long-term operating costs by optimizing design and improving system efficiency; |

| Maintenance and scalability: | Consider the convenience of maintenance and later expansion to adjust the layout. |

ADVANTAGES OF RADIO-SHUTTLE RACKING

- High-density storage: High warehouse utilization;

- High work efficiency: Greatly reduce operation waiting time;

- Flexible operation mode: The access mode of goods can be first-in-first-out or first-in-last-out;

- High safety factor: Reduce the collision between shelves and forklifts, improve safety productivity.

RADIO-SHUTTLE RACKING APPLICATIONS

The radio-shuttle rack is especially suitable for more quantity but less sample industry, such as food, beverage, cold chain, medicine, chemical, daily chemical, tobacco.

RADIO-SHUTTLE RACKING ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Radio-shuttle rack is a semi-automated high-density storage system, which is suitable for storing large quantities and few varieties of goods.

High-density storage, semi-automation, reducing labor costs.

Manufacturing, logistics and warehousing, food and beverage industry, cold chain logistics, etc.

Access to goods is achieved through the shuttle running on the track. It can be divided into two modes: FIFO and FILO.

Install frame protectors at the bottom of the shelves; The shuttle is equipped with an emergency stop function to ensure that it can stop operation immediately in case of an abnormal situation.

Higher initial investment, including costs for shelves, shuttles and management systems; Limited applicability, mainly suitable for large quantities, less varieties of goods storage.

Regularly check the stability of posts, beams and tracks; Regularly clean the tracks and shuttles; Find loose or damaged parts, timely repair.