PRODUCT

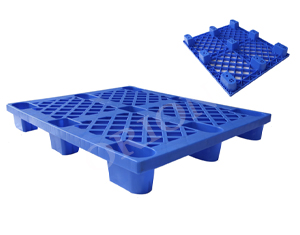

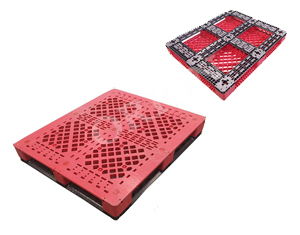

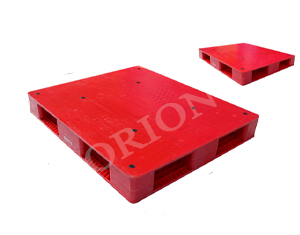

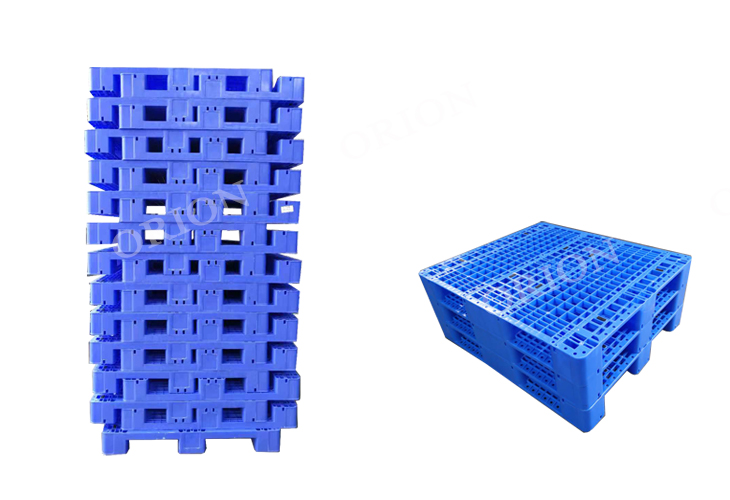

Plastic Pallet

Plastic pallet is a flat-shaped container made of plastic, usually with fork holes for forklift trucks or pallet trucks, used for packing, stacking, handling and transportation of goods.

Plastic pallet are widely used in warehousing, logistics, manufacturing, food, medicine, chemical and other industries.

ADVANTAGES OF PLASTIC PALLET

- Light materialCompared with wood and metal pallets, plastic pallets are lighter in weight, easy to handle and operate, can reduce labor intensity and improve work efficiency.

- Corrosion resistanceHas good corrosion resistance, not easy to be attacked by chemicals, moisture, acid and alkali substances, suitable for all kinds of harsh environment, especially in the chemical industry, food processing and other industries have obvious advantages.

- Hygiene and cleaningThe surface is smooth, not easy to be contaminated with dust, oil, etc., easy to clean and disinfect, in line with the strict requirements of food, medicine and other industries on hygiene conditions.

- Strong durabilityHigh strength, good toughness, good impact resistance, can bear large weight, long service life under normal use, can be reused many times, reducing the cost of use.

- Environmental protection and energy savingSome plastic trays can be recycled, in line with the concept of environmental protection.

- Various specificationsAccording to different cargo size, weight and transportation requirements, design and production of various specifications of plastic pallets, but also can add anti-slip pads, steel pipes and other accessories to meet the diversified logistics needs.

pallet's load-capacity

What is the difference between dynamic load, static load and load bearing on the shelf of the plastic pallet?

HOW TO CLASSIFY PLASTIC PALLET

Plastic pallets can be divided into the following types according to their structure:

HOW TO CHOOSE THE PLASTIC PALLET

Select the right pallet according to the weight, size, shape and packing method of the goods. For example, for heavy goods, “川” type or “田” type with strong carrying capacity should be selected; For irregularly shaped goods, consider using customizable plastic pallets.

If it is used in a humid and corrosive environment, the corrosion resistance advantage of plastic pallets is particularly important; In low temperature environments such as cold storage, plastic pallets with good low temperature performance should be selected to prevent brittleness.

Pallet selection should be combined with forklift trucks and other handling equipment. If the counterweight forklift is used, pallets of various structures can be selected; If you are using a narrow channel forklift or pallet stacker, you may need to select a pallet whose bottom structure is suitable for its forklift.

In the selection, we should comprehensively consider the procurement cost, use cost and long-term benefits, and choose according to the actual situation of the enterprise.