PRODUCT

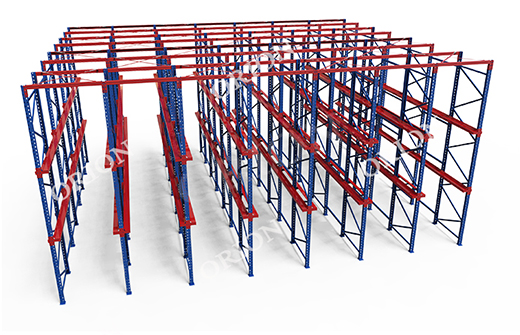

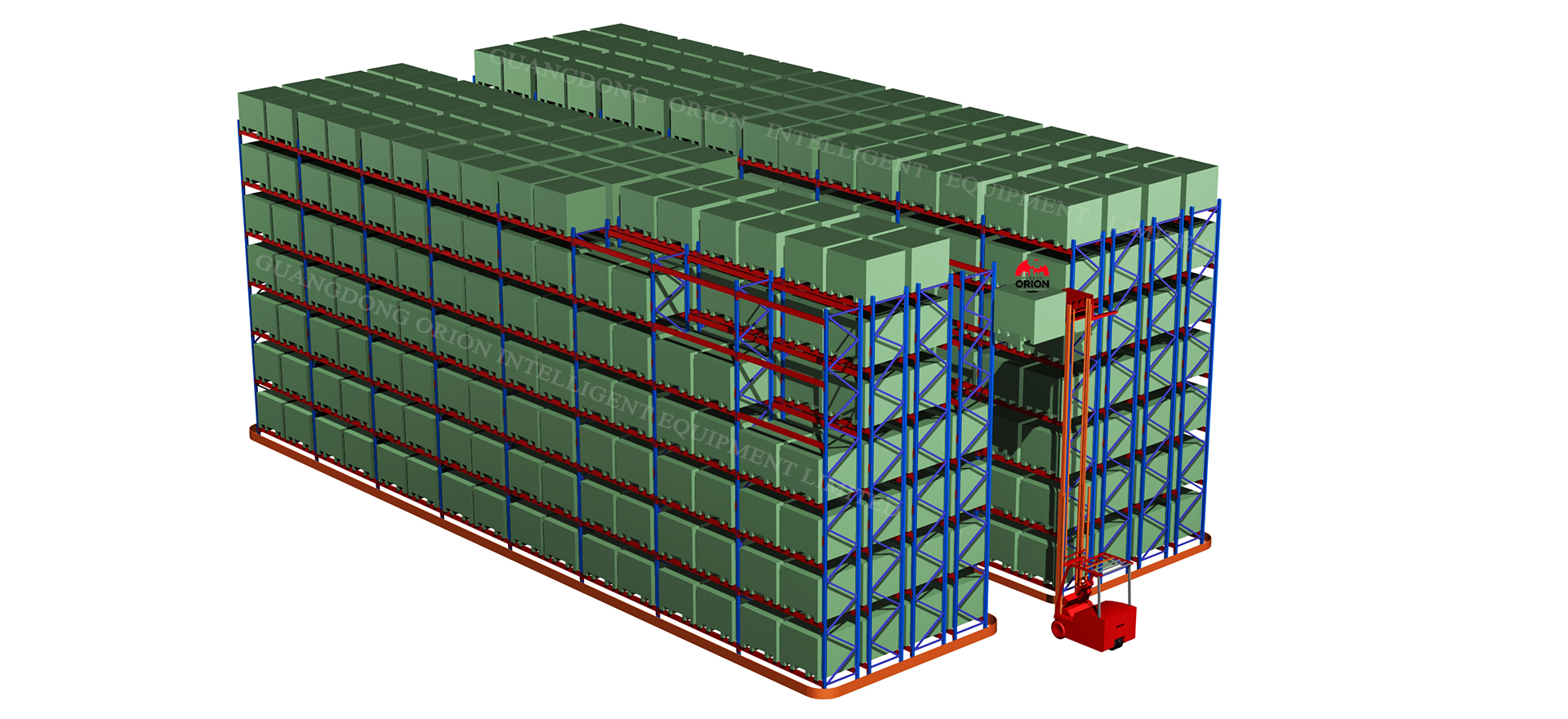

Double Deep Pallet Rack:

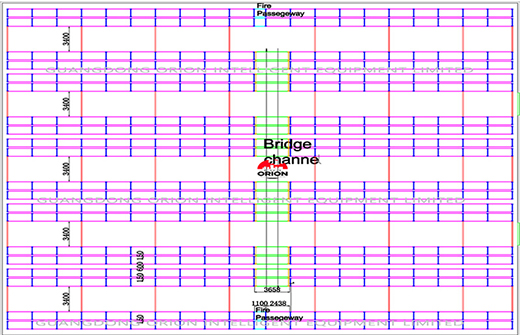

Double-deep pallet rack is derived from the selective rack,with simple structure and high storage capacity, which effectively alleviates the storage requirements that the ordinary pallet rack cannot meet, and doubles the inventory.

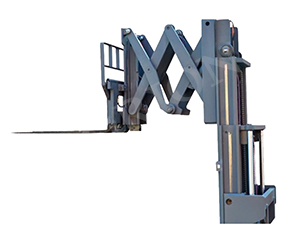

This kind of shelf needs to use a forklift with a telescopic fork arm to access the goods, and the forklift channel needs to be designed above 3.3m.

Double-depth shelves are widely used in tobacco, food and beverage, packaging and other industries.

DESIGN FACTOR

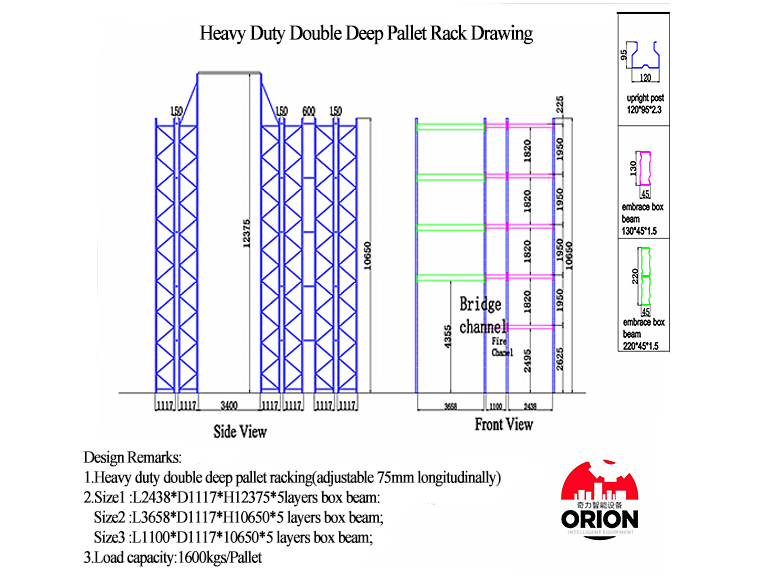

| Warehouse space planning | According to the height and area of the warehouse to determine the total height and layout of the shelves, make full use of vertical space. |

| Load-carrying capacity design | According to the weight of the storage goods to determine the bearing requirements of the shelf, to ensure that the shelf structure can withstand the maximum load. |

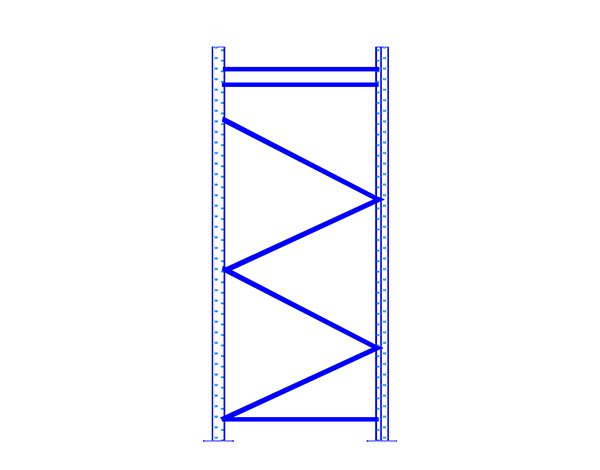

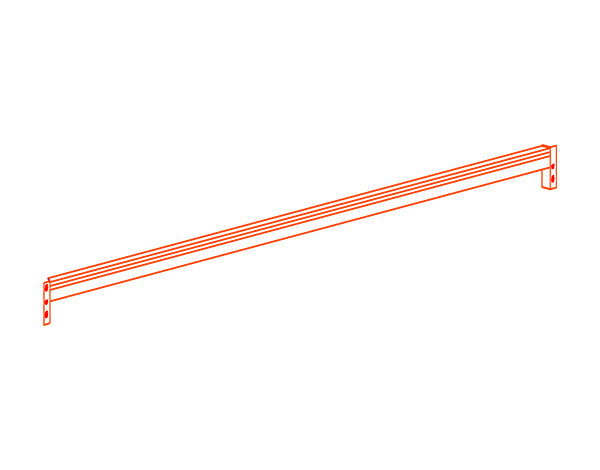

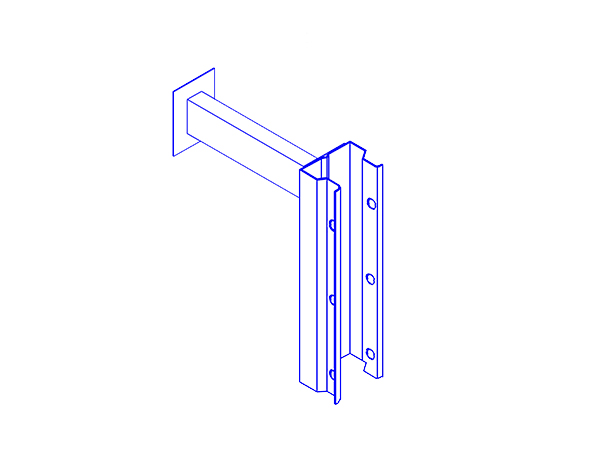

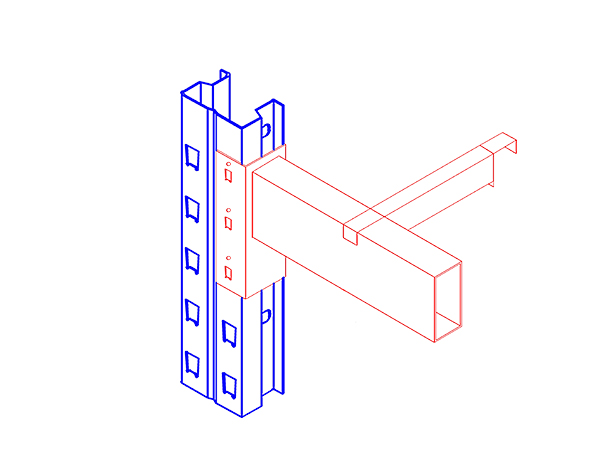

| Shelf design | Select the appropriate posts and beams according to the load bearing. |

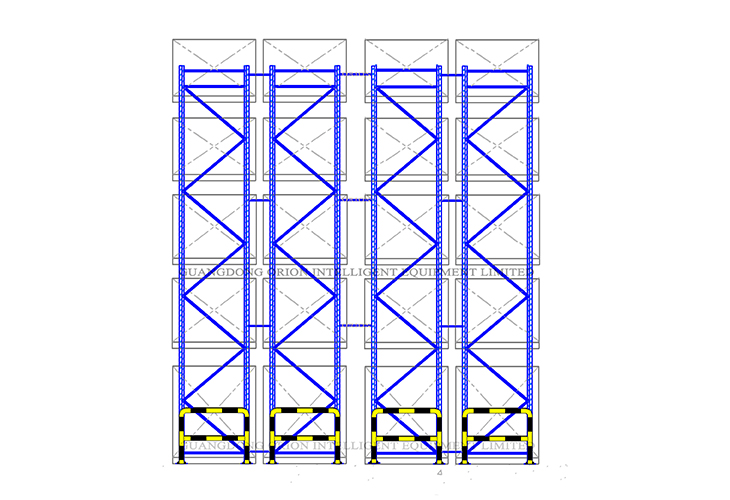

| Forklift selection | Select a dedicated double deep forklift to ensure access to the second row of goods. |

| Channel design: | The width of the channel is determined according to the model of the forklift and the turning radius, usually 2.7-3.3 meters. |

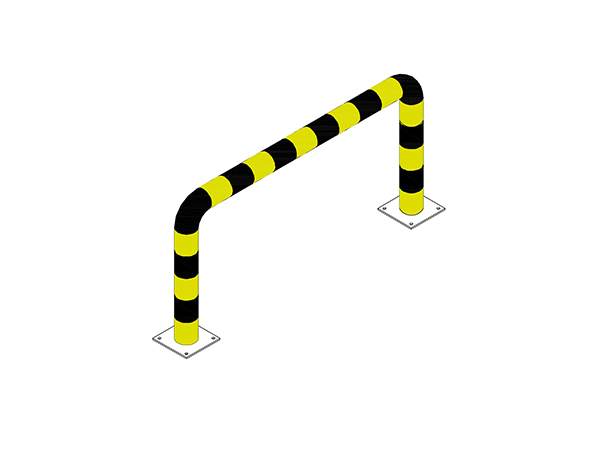

| Safety design | Install anti-collision guardrail, safety pin to ensure the stability and safety of the shelf. |

ADVANTAGES OF DOUBLE DEEP PALLET RACK

- Improve space utilization: The dual-row storage design maximizes the utilization of warehouse space and reduces the number of channels;

- Strong carrying capacity: The use of high-strength materials, able to carry heavy cargo, usually carrying capacity of 1-2 tons/layer;

- Reduce storage costs: Increase storage density and reduce storage costs per unit of goods;

- Suitable for mass storage: Suitable for storing large quantities and few varieties of goods, such as raw materials or finished products;

- Economical and practical: While improving the storage density, the cost is relatively low and the cost performance is high;

- Stable structure: The use of high-strength materials and back rod design to ensure the stability and safety of the shelf.

DOUBLE DEEP PALLET RACK APPLICATIONS

DOUBLE DEEP PALLET RACK ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

The shelf is designed into double rows of parallel storage shelf type. It is derived from the pallet rack, simple structure, can effectively alleviate the storage requirements,and double the inventory of the pallet rack.

High space utilization, large storage capacity, certain selectivity, need to be equipped with a special forklift.

Double-deep rack are widely used in tobacco, food and beverage, manufacturing and other industries. Suitable for storing standardized pallet goods, low turnover goods, etc.

The double-deep rack adopts the FILO access method. For accessing the goods in the back row, need to carry out the goods in the front row.In order to improve the utilization rate of the warehouse, when stocking, store the back shelf first, and then store the front shelf .When shipping, Try to remove the same row at one time, otherwise it may affect the inventory utilization rate or warehouse operation efficiency.

The maximum height of the rack is usually limited by the clear height of the warehouse and the operating height of the forklift, which can generally reach 10-12 meters.

The width of the channel depends on the model of the forklift and the turning radius, which is usually 2.7-3.3 meters. Ensure that the channel width can meet the operation requirements of forklift trucks.

Access flexibility is low, rely on special forklift, inventory difficulty increases.