PRODUCT

Push Back Pallet Racking:

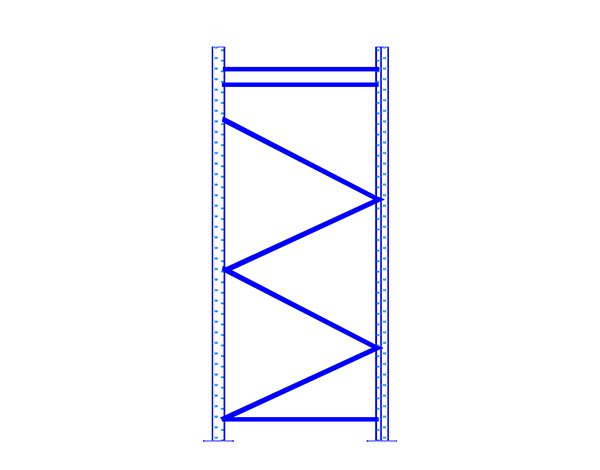

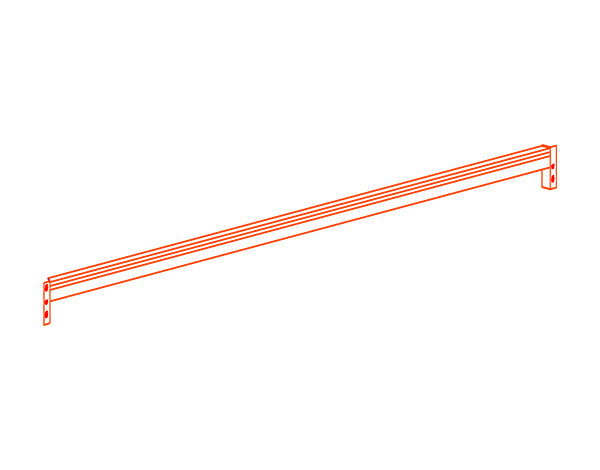

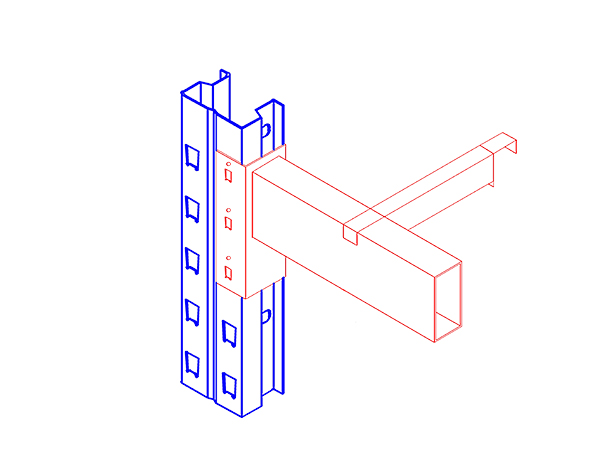

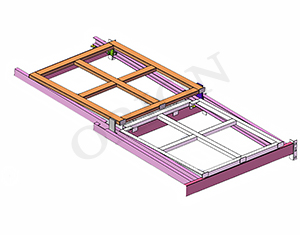

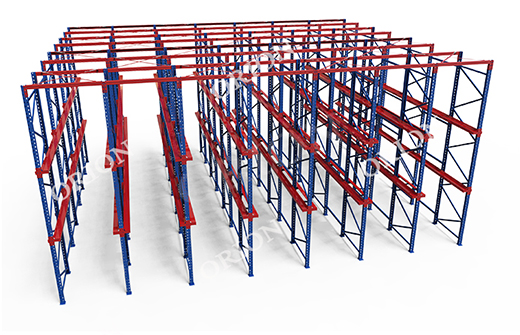

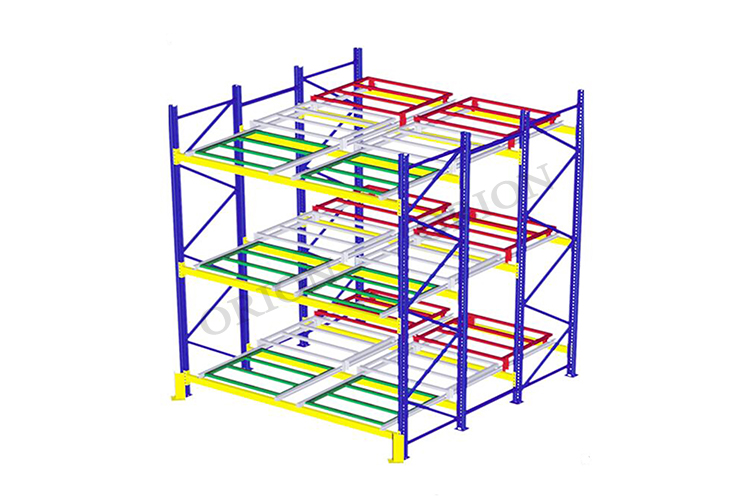

Push-back racks are also called press-in racks, which are composed of pallet racks, tracks, and trolleys.

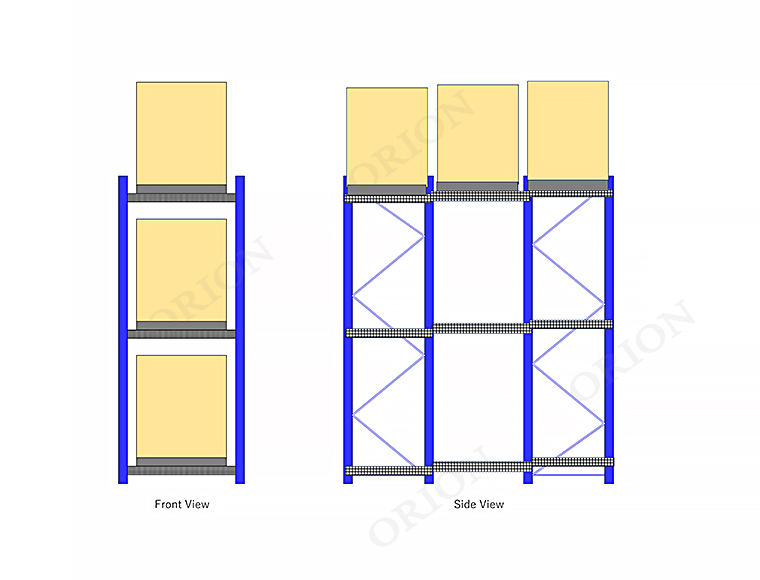

The trolleys are arranged in a nested arrangement and run on a track with a set inclination angle, the goods that enter later will push the goods that enter first in order. When picking up the goods, take the outermost pallet first. When the goods on the outside are taken out, the goods inside will automatically slide down due to gravity. Implement first-in, last-out storage.

The storage depth of this kind of racks is suitable for 2-4 pallets, and the deepest can reach 5 pallets.

DESIGN FACTOR

| Warehouse space and layout | Rationally plan the position of shelves and ensure that the channel width is enough to facilitate the operation of forklifts and personnel. |

| Cargo characteristics | According to the size and weight of the goods to determine the load-bearing and height of the shelf. |

| Storage requirements | Determine the depth of the shelf according to the storage requirements, usually the depth of the push-back shelf is 2-5 pallets. |

| Shelf structure | Design a solid shelf frame to ensure that it can withstand the weight and thrust when fully loaded. |

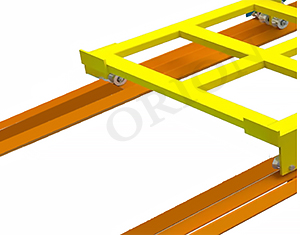

| Track | Reasonably design the tilt Angle of the track to ensure that the tray can slide smoothly. |

| Trolley | Select a high quality trolley to ensure its carrying capacity and smooth sliding. |

| Maintenance plan | Make regular maintenance plan, timely lubrication and replacement. |

ADVANTAGES OF PUSH BACK PALLET RACKING

- Space saving: By reducing the space of the warehouse, it can effectively improve space utilization, especially suitable for limited storage space;

- Versatility: Push-back pallet racking are suitable for placing various types of goods, including pallets, drawers, boxes, etc., with good versatility;

- Structural stability: Because the forklift does not enter the system, the post is less damaged;

- High working efficiency: The forklift truck only needs to operate at one end of the shelf channel, which greatly improves the storage and transportation speed.

PUSH BACK PALLET RACKING APPLICATIONS

It is usually used in storage space is extremely limited, but storage capacity must be increased or time requirements for goods are not high.

PUSH BACK PALLET RACKING ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Push-back rack is a high-density storage system, through the push-back design to achieve multi-layer cargo storage and FILO access mode. It is widely used in scenarios requiring high-density storage, efficient access and flexible management.

The main structure is similar to the pallet rack, but a special sliding trolley is installed on the beam. The pallet are placed on the trolley, which can slide smoothly on the track. The track usually has a certain slope so that the cargo can slide forward under gravity.

It uses a sliding trolley to carry the cargo, and relies on a forklift to push the goods backward from the shelf passageway to store them. When picking up, the goods located at the front are removed, and the goods behind them automatically slide forward to the pickup position under the action of gravity.

High space utilization, FILO storage, high storage efficiency.

Food and beverage industry, logistics warehousing center, manufacturing raw material storage.

Regularly check the shelf structure, clean the track and sliding trolley, and check the sliding condition of the goods.

There are limitations to the access of goods, the cost is higher than the cost of ordinary shelves, and the ground bearing requirements are high.