PRODUCT

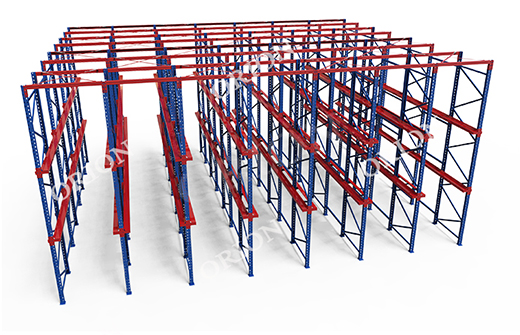

Mold Rack:

Mold rack is mainly used to store various molds, steel materials, motors, engines and other heavy objects. Drawer-type mold rack adopts bearing combination, and each drawer can be pulled out separately by 60%-100%, each layer of drawers can be increased or decreased, and the number of grids can be connected unlimited.

The top is equipped with mobile crane and hoist,which can access the mold independently,save time and effort.

KEY POINTS OF DESIGN

| Load Capacity | Choose the appropriate load-bearing specifications based on the weight of the molds. |

| Size Compatibility | Ensure the size of the mold rack matches the molds to avoid space waste. |

| Material Selection | Select rust-proof and corrosion-resistant materials according to the environment. |

| Mobility: | If frequent movement is required, opt for mold racks with wheels |

| Safety | Ensure a sturdy structure |

ADVANTAGES OF MOLD RACK

- Save space: Can store dozens of sets of small and medium-sized molds with an area of only 1.8 ㎡,save 50% space;

- Standardized management: Easy to manage, find and maintain;

- Structure simple: Easy to disassemble, transport and install;

- Improve efficiency: The top is equipped with mobile crane frame and an additional hoist, it can independently lift the mold without a large crane or forklift, which saves time and effort;

- Safety:Reduce the work intensity and ensure the health of employees.

MOLD RACK APPLICATIONS

MOLD RACK ACCESSORIES

PACKAGING AND TRANSPORTATION

In order to ensure product quality and safety, different products have different packaging methods, commonly used wrapping film, bubble bag, carton, wood frame.

FAQS

Mold rack is a kind of storage equipment specially used for storing all kinds of molds.

Stable structure, strong load-capacity, easy access.

Commonly used materials are high quality cold rolled steel and U-steel. Cold rolled steel has good strength and toughness and smooth surface. U-steel has high rigidity and stability, and is often used in the frame structure of the mold rack to increase the overall carrying capacity.

Suitable for injection mold, stamping mold, metal processing and other industrial mold storage management.

The load-capacity of the mold rack is related to the type and specification. The drawer mold rack is usually between 1T-3T per layer.

Factors need to be considered when selecting the mold rack: mold size and weight; Access frequency; Workshop space and safety.

Regular inspection of bolts; Keep tracks or drawers clean; Avoid overload or unbalance load storage.