Fully Open Mould Rack Implementation Case: Solving High-Volume Mould Storage Challenges

The existing mould racks have been in use for too long, and their drawing plates have become deformed, posing potential safety hazards;

The existing mould racks are semi-open, so the moulds cannot be fully exposed, which affects efficiency;

Difficult to access and high safety risks;

The load-bearing capacity and stability are insufficient;

The management is chaotic.

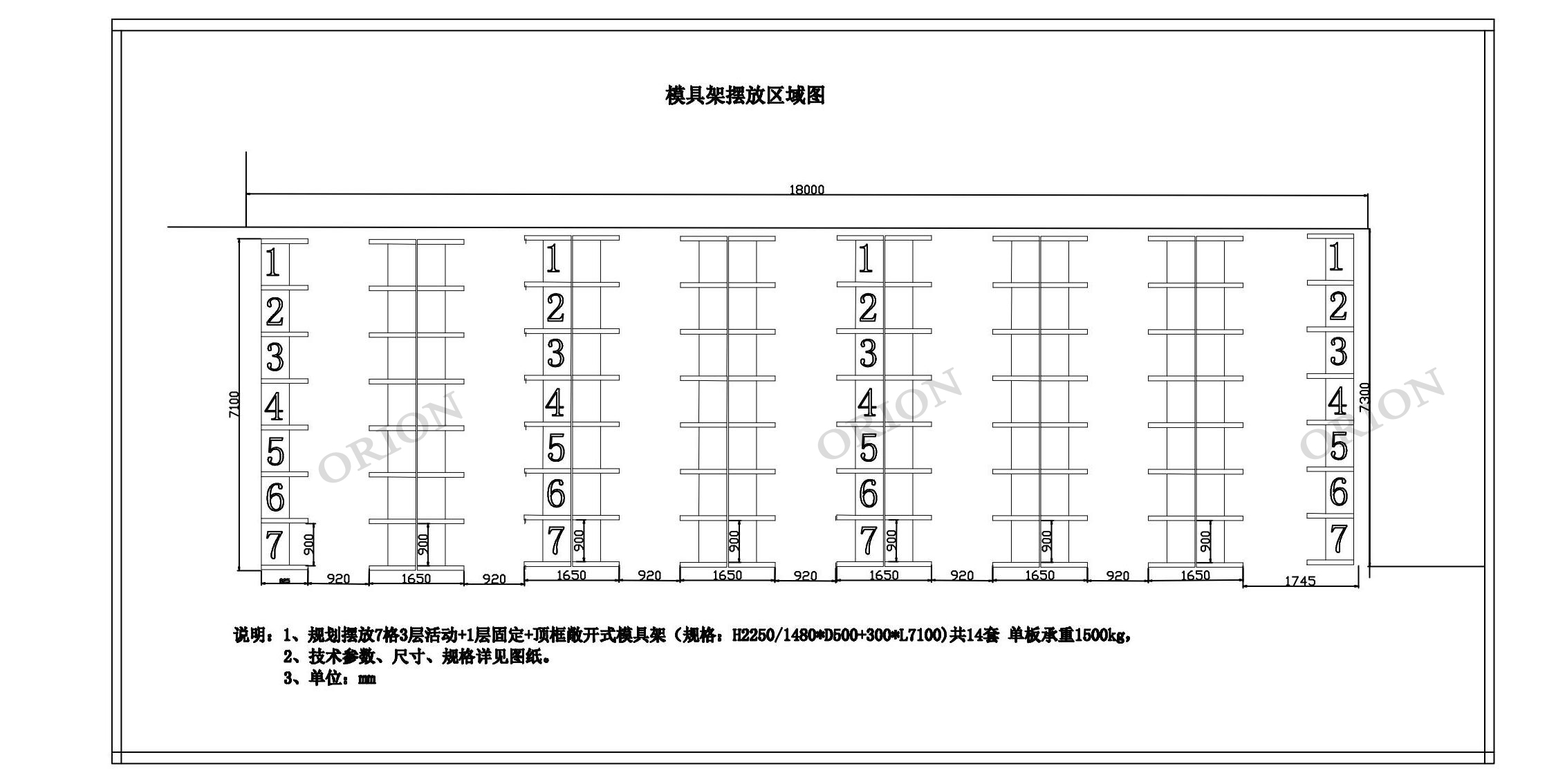

ORION’s baseline plan was as follows:

Frame structure: Three-column framework, using 10# thick channel steel;

Opening method: Fully open type. Each layer has an independent drawer structure that can be fully pulled out along the guide rail.

Number of storage layers and layer height: The height of each layer can be adjusted. A total of 4 layers are designed, and the height of a single frame structure is 2.25 meters.

Number and layout of racks: A total of 6 sets of fully open mold racks were custom-made. Each set has 7 compartments, with a total length of 7.1 meters and a depth of 500 + 300 mm.

Highlights of the plan:

Space optimization: Through the "multi-layer + fully open" design, a single set of frame can store 8 to 10 sets of molds (4 layers, with 2 to 3 sets per layer).

Efficient Access: The fully open drawer enables the inner molds to be pulled out directly to the channel area without moving the outer molds. This shortens the single retrieval time by 75% and enhances efficiency. At the same time, in conjunction with QR code labels, it solves the problem of "difficulty in finding molds".

Safety upgrade: Guide rail buffer device + Safety pin to prevent sliding out.

| Height of racks: | 2250 mm |

| Width of racks: | 500+300 mm |

| Total length of racks: | 7100 mm |

| Number of load levels: | 4+retaining plate |

| Load-capacity: | 1500kgs/drawer |

| Total capacity of storage: | 168 gird |

| Warehouse temperature: | Normal temperature |

In this case, the full-open mold rack solved issues with the old rack, including deformation, difficult access, and safety hazards. Its three-column structure and full-open drawer design ensure stable load-bearing and efficient access. It optimizes space, doubling utilization, with each unit storing 8-10 sets of molds. Combined with labeling, it also simplifies mold locating, providing a reliable solution for enterprise mold management.