Case Study of Drive-in Racking System for Automotive Parts Manufacturers

The cooperative client in this case has experienced rapid expansion of its business in recent years. However, its existing warehousing model has gradually revealed serious issues, with specific pain points in terms of needs focusing on the following three aspects:

Extremely low utilization rate of warehousing space;

Low efficiency of inventory turnover;

High pressure on cost control.

ORION's baseline plan was as follows:

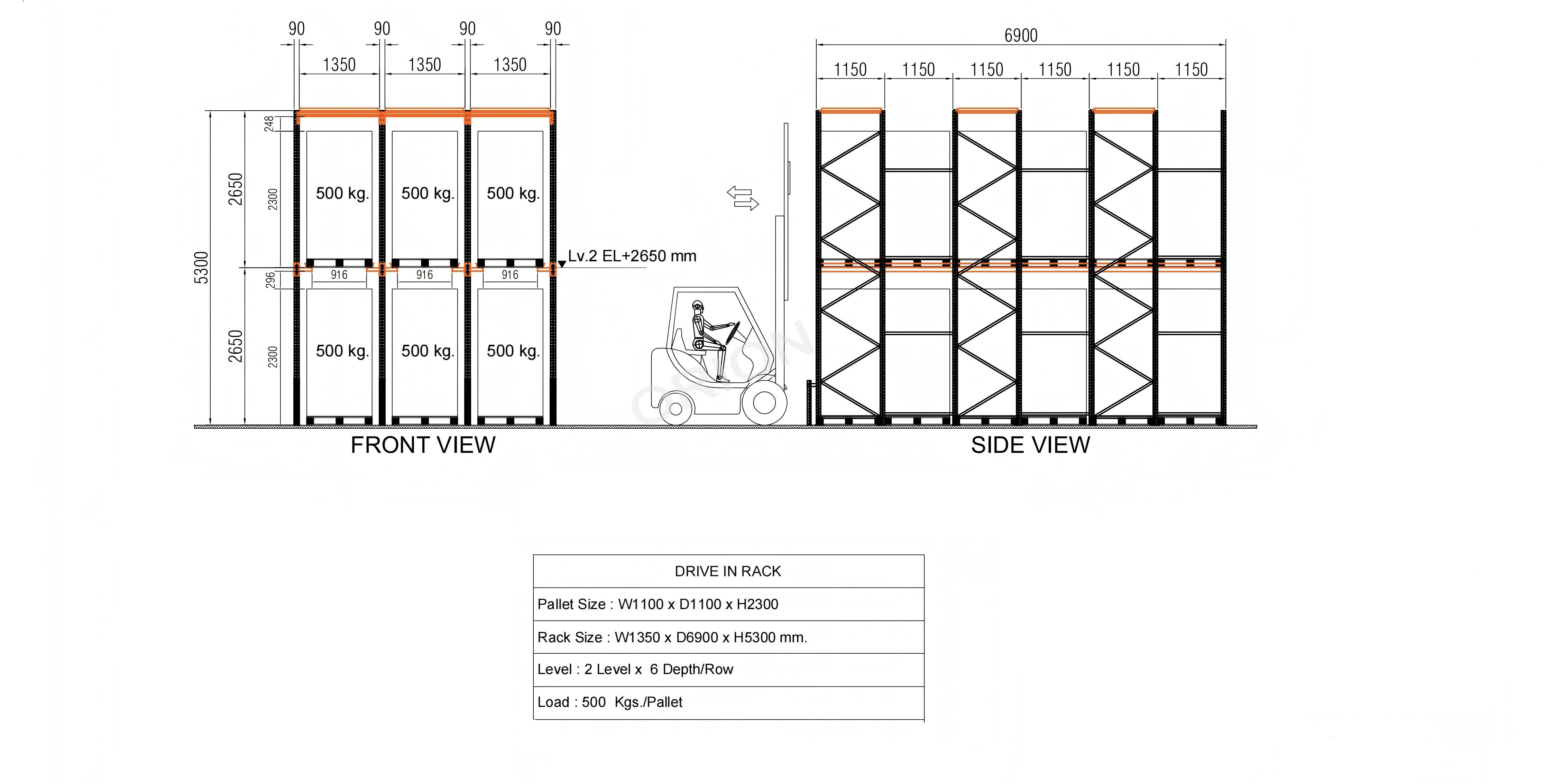

Load-bearing design: Based on the customer's requirement, the design is made to support a load of 500kgs per layer;

Height design: In line with the customer's needs for different sites, two height options are designed: 5.3/7.0m;

Length Design: Based on the site dimensions, the shelf length is designed to be 5.75m / 6.9m.

Depth Design: According to the site dimensions, 5-depth and 6-depth configuration is designed for the client.

| Height of racks: | 5300/7000mm |

| Width of racks: | 1350mm |

| Rack Length: | 6900mm |

| Layers of Racks: | 2 layers |

| Storage Capacity | 3264 pallets |

| Load-capacity: | 500kgs/layer |

| Depth | 5 depth/6 depth |

| Warehouse temperature: | Normal temperature |

Project Insight:

Precise Alignment with Requirements is the Premise: Drive-in racking is not a "one-size-fits-all solution"; its applicable scenarios have clear characteristics: the goods must be standardized and in large quantities with moderate turnover frequency, and the warehouse must have a certain height to give full play to the advantages of vertical space.

Customized Design is the Core: Customized design can not only maximize the performance of the racking but also avoid resource waste and reduce the client’s initial investment costs.