Application of Cantilever Racks in the Steel Processing Industry

Low Space Utilization: Previously, the enterprise stored steel directly on the warehouse floor. This wasted significant space, hindered rational planning, and resulted in extremely low utilization—with actual storage capacity only around 30% of the theoretical limit;

Improved Access Efficiency: The disorganized original storage method caused long access times and inconvenient handling;

Steel Damage: Floor-stacked steel was prone to collision/extrusion damage; long-term floor contact also led to rust and corrosion, degrading quality and increasing the enterprise's costs.

ORION's baseline plan was as follows:

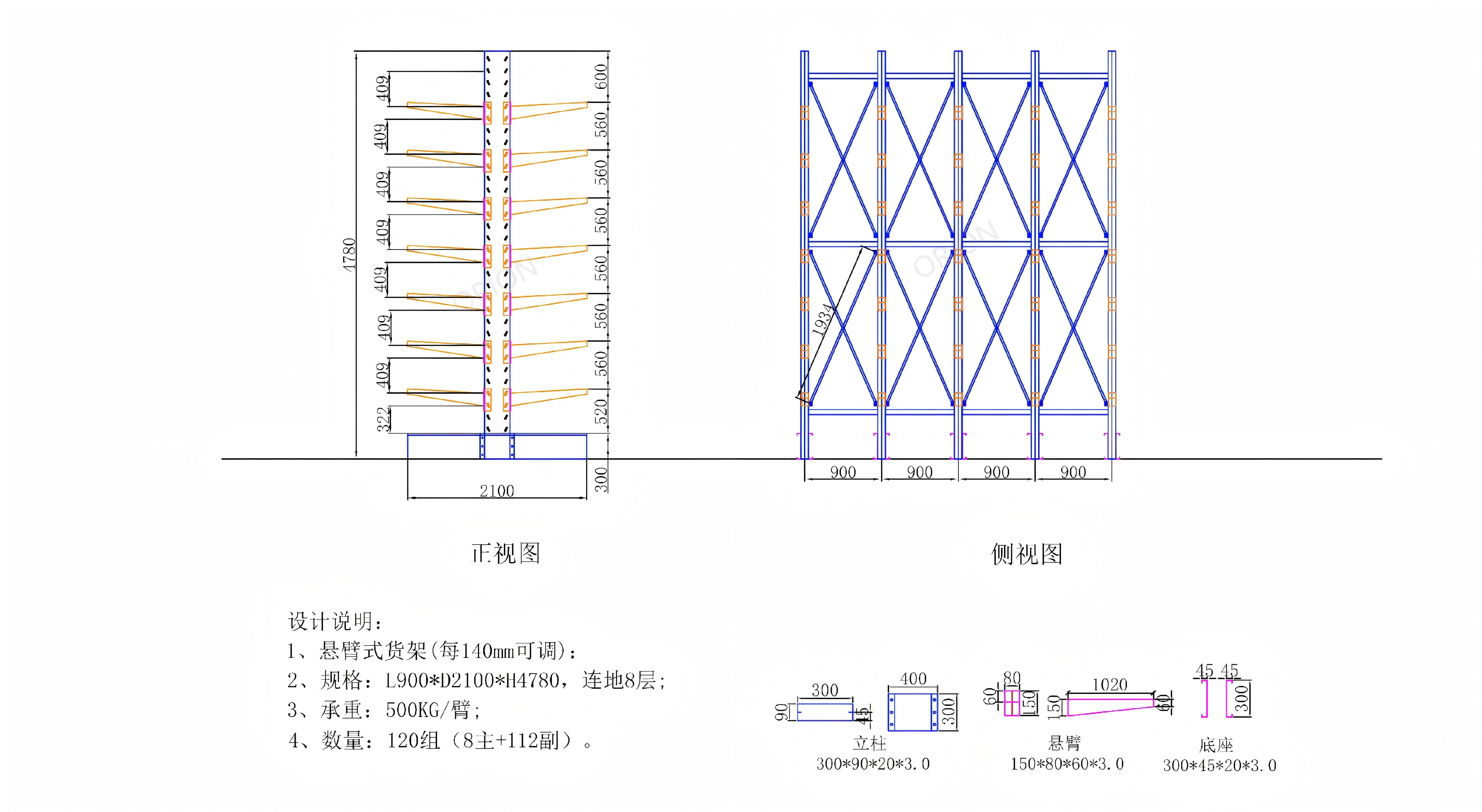

To meet the client's needs, the project team designed a "double arms + zoned management" customized shelf system after on-site surveying, cargo characteristic analysis and load calculation.

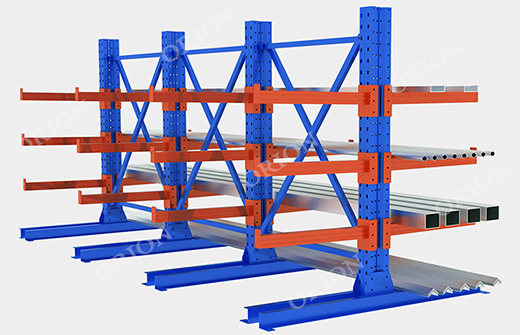

Shelf structure: Adopts a combined structure of "columns + cantilever beams + reinforced diagonal braces", with anti-fall bars added at the end of cantilevers to eliminate safety hazards;

Storage layout: Based on the type and specification of the enterprise’s steel, the cantilever racks are reasonably laid out. Frequently used steel is placed on lower layers for easy access; infrequently used steel is stored on higher layers. Meanwhile, steel of different specifications is classified and stored, with clear signs on each storage location for workers to quickly find the required steel;

Supporting equipment: To match the cantilever racks, the enterprise is equipped with corresponding handling equipment such as overhead cranes and forklifts. The combination of these equipment and cantilever shelves greatly improves the efficiency of steel access.

| Height of racks: | 4780mm |

| Layers of Racks: | 8 layers |

| Load-capacity | 500kgs/arm |

| Quantity | 8 start racks +112 connect racks |

| Type | Double cantilever arms |

| Warehouse temperature: | Room temperature |

Project Insight:

By introducing cantilever racks, the steel processing enterprise has successfully solved its steel storage challenges, improved warehouse management efficiency, and reduced costs—laying a solid foundation for its sustainable development. The advantages of cantilever racks in steel storage have been fully demonstrated, providing valuable reference for other similar enterprises.