How Pallet Racks Enhance Warehousing Capacity in Logistics

Headquartered in Japan, the company specializes in manufacturing logistics services. It offers customized support for key manufacturing needs, including high-mix, low-volume component logistics, real-time inventory management, and just-in-time delivery.

To help global customers optimize supply chain efficiency, the company has established warehouses in multiple countries and regions worldwide. In its Southeast Asian market expansion, Thailand—an important manufacturing hub in ASEAN—is one of the key regions for the company's growth. To better meet the needs of Thai market customers in terms of material storage and turnover efficiency, the Thai warehouse has purchased a new batch of heavy-duty pallet racks.

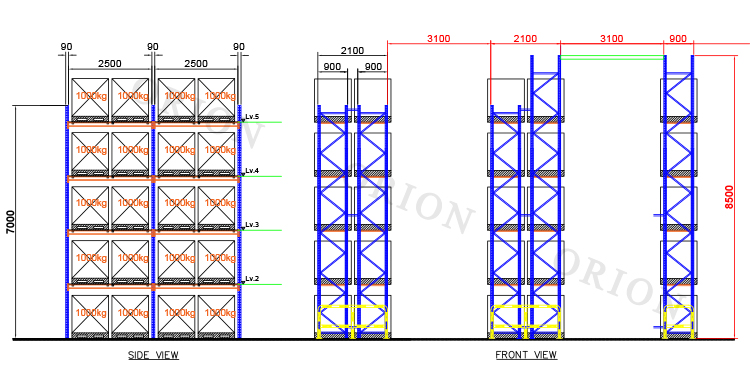

ORION's baseline plan was as follows:

Height Design:Two height options (7m / 8.5m) are designed to cater to customers' different cargo storage needs.

Aisle Design: Two width options (3.6m / 4.1m) are designed based on the customer's site conditions and actual operational requirements.

Span Design: The rack cargo position span is set to 2.5m / 1.3m according to the maximum cargo size. This ensures each cargo position can hold 1-2 standard pallets or full cases, avoiding space waste.

Support Beam Configuration: Each layer is equipped with 4 support beams to enhance load-bearing stability.

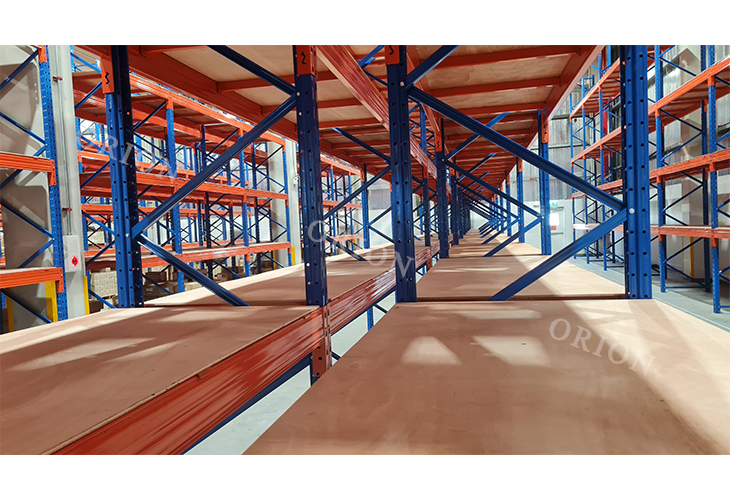

Plywood Addition: A wooden board is added to each layer to accommodate more non-standard cargo and protect both the cargo and the racks.

| Height of racks: | 7000/8500mm |

| Width of racks: | 2500/1300mm |

| Number of layers: | 4+G layers |

| Load-capacity: | 2000kgs/layer |

| Quantity: | 23 start racks + 179 connect racks |

| Total storage capacity: | 1775 pallets |

Summary:

To meet the material storage and turnover needs of customers in the Thai market, this Japanese company has developed a customized heavy-duty pallet rack solution for its Thai Network. This solution not only efficiently meets customers' current storage and operational needs through tailored height, span, and reinforcement designs but also provides long-term support for customers' business growth and the company's in-depth development in the Thai market, thanks to its sufficient storage capacity and flexible modular structure.

As a core infrastructure for logistics services, the customization level of heavy-duty racks is crucial. It directly determines the compatibility of customers' cargo storage and the smoothness of operational processes, thereby profoundly influencing the overall operational efficiency of customers' supply chains. It serves as a key link connecting logistics services and customer value.