The importance of correct operation of logistics handling equipment

In today's rapidly evolving logistics industry, the skills and knowledge of material handling equipment operators are a core element in ensuring the safe and efficient operation of warehouses.

According to relevant data, about 24% of warehouse accidents are directly related to the lack of professional training of operators, which highlights the urgency of strengthening operator training in warehouse management. In this context, improving the quality of operator training has become the key to ensuring warehouse safety, reducing operating costs, and improving production efficiency.

What practices should operators follow

Safety check:

Check the performance of the device before operation and ensure that the device is normal. Report and repair faults in time.

Speed control:

Avoid speeding and strictly observe the speed limit set by the warehouse. High-speed driving increases the likelihood of collisions with shelves and other equipment, threatening warehouse safety and operational processes.

Correct handling of the goods:

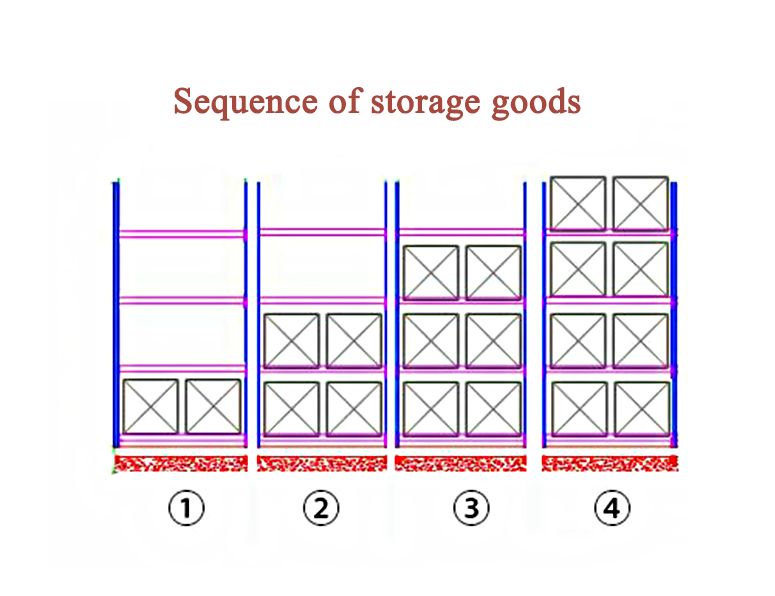

It is strictly prohibited to overload, ensure that the weight of the goods does not exceed the rated load of the equipment; At the same time, pay attention to stacking goods evenly to prevent unstable shelves or falling goods due to uneven weight.

Stay focused manage your work time properly:

Avoid non-operational activities during work to ensure concentration. Operators should reasonably arrange rest to ensure that they are energetic at work and reduce the risk of operational errors caused by inattention.

Receive professional training and qualification:

Actively participate in comprehensive and professional training courses to learn the correct operation methods, safety knowledge and emergency handling skills of the equipment.

The impact of improper operation on warehouse operation

Rising cost of damaged goods:

Non-standard operation methods can easily lead to damaged goods. These losses include not only the value of the goods themselves, but also re-procurement, replenishment and possible customer compensation costs.

Increased maintenance costs:

Incorrect operation will not only accelerate equipment wear and cause frequent breakdowns, but also cause damage to warehouse shelves.

Low operational efficiency:

Frequent accidents and equipment failures inevitably lead to the interruption of warehouse operations. Operational stagnation affects the efficiency of moving goods in and out of storage, leading to delays in order delivery and reducing customer satisfaction.

Increased risk of safety incidents:

Lack of training exposes operators to higher safety risks on the job.

Effective strategies for problem solving

The phenomenon of improper operation of handling equipment operators not only buries security risks for warehouse safety, but also seriously hinders the process of cost reduction and efficiency increase of enterprises. To this end, enterprises can start from multiple dimensions such as training, management, and technology application to systematically solve problems.

Optimize the training system:

Carry out comprehensive induction training; Implement regular skills improvement training, and continuously improve the operator's operating skills; Develop a sound emergency plan, and organize operators to carry out emergency drills.

Strengthen safety awareness education:

Regularly organize safety knowledge lectures, invite professionals to explain warehouse safety regulations, accident cases and safety precautions, and improve their safety awareness and self-protection awareness.

Strengthen the management mechanism:

Make clear operation standards and assessment system; Strengthen on-site supervision and guidance.

Conclusion

Proper operation has a crucial impact on warehouse safety and operational efficiency, and enterprises should attach great importance to operator training. Through professional skills training, safety awareness education and emergency handling ability training, improve the overall quality and business level of operators. Only in this way can we create a safe and efficient warehouse operating environment, achieve sustainable development of the enterprise, and remain invincible in the fierce market competition.

Previous

Previous