Warehousing crisis and coping strategies under the domino effect

In modern warehousing systems, racks are the key infrastructure for efficient storage and cargo management. They are like the "skeletal framework" of storage space, supporting the storage of all kinds of goods and ensuring the smooth progress of warehouse operations. However, this seemingly solid and stable shelf system may cause a series of catastrophic consequences due to a seemingly insignificant factor - the damage of the column, which is what we often say is the domino effect.

Upright post in the core position of the racking system

The upright post, as the core load-bearing component of the shelf structure, plays a crucial role in the entire storage system. It is responsible for the vertical transfer of cargo weight to the ground, ensuring the stability of the shelf system. At the same time, the column is also a key node connecting the box beam, cross H&D brace and other components, through close cooperation with them, together to build a stable storage framework, maintain the integrity and rigidity of the shelf structure.

The hidden crisis behind the post damage

When the post is damaged,even if the damage is slight, it can not be ignored. From a mechanical point of view, the load-carrying capacity of the damaged column is reduced, and the adjacent post and other structural components are required to bear additional loads.Research data show that when the strength of the post is reduced by 5% due to damage, the stress borne by the adjacent components will instantly increase by 30%-40%, which undoubtedly greatly exceeds their design load limit.

With the continuous accumulation of stress, the box beam of the shelf may bend and deform because of excessive pressure, and the bolts and solder joints of the connection parts will gradually loosen, and the originally closely connected structure will become shaky. This unstable state makes the shelf's resistance to subsequent external forces extremely fragile, and slight external forces may cause more serious structural damage or even collapse.

The cost of ignoring upright post damage

1. Economic loss: The loss of goods is often the most direct economic cost. The cost of repairing or replacing damaged shelves is also very high, and the purchase, installation and commissioning of new shelves require a large investment.

2. Operation disruption: The stagnation of warehouse operations will disrupt the rhythm of the entire supply chain, delay the delivery of orders, and decrease customer satisfaction. For some seasonal or time-sensitive goods, the loss of missing the sales season is difficult to estimate.

3. Safety risks and legal liability: Safety accidents caused by the collapse of shelves may lead to serious injuries or even death of employees. Enterprises not only have to bear various costs of employees, but also may face severe penalties and legal proceedings from regulatory authorities, and their reputations will be greatly damaged.

4. Damaged compliance and partnerships: After an accident, companies need to be investigated by various regulatory agencies, which can take a lot of time and energy. Companies can also face hefty fines if they have lapses in security compliance. In addition, partners may also question the stability of cooperation.

Effective strategies to prevent the domino effect

In order to avoid the domino effect caused by the collapse of shelf posts and ensure the safe and efficient operation of warehousing operations, enterprises can take a series of comprehensive and effective preventive measures.

1. Regular inspection system: Establish a strict daily inspection mechanism, arrange professionals to regularly carry out detailed inspection of the shelves, focusing on whether the column has deformation, wear, cracks and other signs.

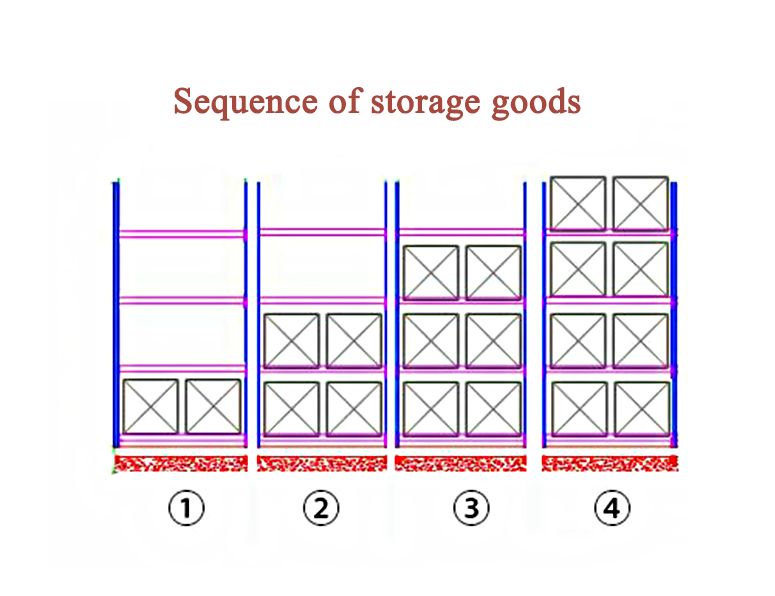

2. Strict load management: The maximum load bearing weight is marked in the prominent position of the shelf, and the staff is strictly required to stack the goods in accordance with the regulations.

3. Personnel training and safety awareness enhancement: Strengthen safety training for warehouse employees, enhance safety awareness, and organize safety drills.

4. Physical protection measures: Protective facilities such as guardrail and anti-collision column are set up around the shelves to reduce the risk of forklift collision with the column. Install protective sleeves for columns to enhance their impact resistance. Use high-strength safety pins to prevent loose connections.

5. Create a safety culture atmosphere: Integrate the safety concept into the cultural construction of the enterprise, from the management to the grass-roots staff, to form a good atmosphere for everyone to pay attention to safety and participate in safety management.

Conclusion

The domino effect caused by the collapse of shelf posts has brought challenges to the warehousing industry that cannot be underestimated. It will not only cause huge losses to the economic interests of enterprises, but also seriously threaten the life safety of employees and affect the normal operation and market reputation of enterprises. However, by taking scientific and reasonable preventive measures, strengthening the daily maintenance management of the shelves, improving the safety awareness of employees, enterprises can effectively avoid the occurrence of this risk.

In a highly competitive market environment, companies should not view security as a cost, but as an important investment to ensure operational stability and enhance competitiveness. Only by paying attention to shelf safety and actively preventing the domino effect can we create a safe and efficient environment for warehousing operations and realize the sustainable development of enterprises.

Previous

Previous